ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, announces the latest release of its CAM components, ModuleWorks 2017.12, the third major update of 2017.

ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems around the world today.

In this latest release, multi-axis collision avoidance has become even safer by taking the shape of the holder and arbor into consideration, and it is now possible to create deburred edges with a user-defined constant depth or width. These and further highlights of the 2017.12 release are described below.

5-Axis Machining

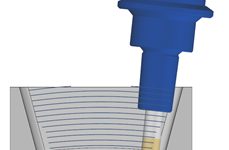

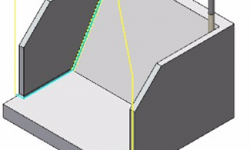

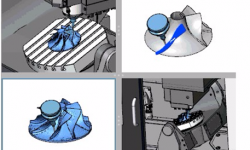

Dynamic collision avoidance between the tool, arbor, holder and machining surfaces

This new feature considers the shape of the holder and arbor during the toolpath calculation to avoid collisions between the entire tool and the machining surfaces.

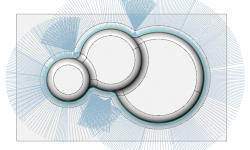

Tool axis smoothing for surface based and geodesic machining

Before tool axis smoothing After tool axis smoothing

Tool axis smoothing allows users to smooth the tool axis when machining to eliminate jerky movements. Rotary smoothing as well as linear axis smoothing optimizations are possible.

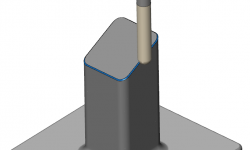

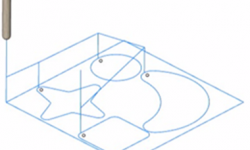

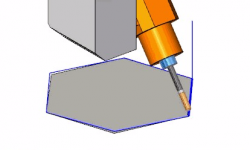

Deburring

This new feature creates a deburred edge with a user defined constant depth or constant width.

3-Axis Machining

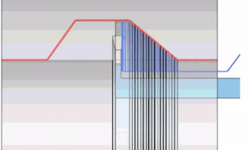

Breakthrough overlap for adaptive roughing

This new option enables users to specify an additional area that requires machining after the tool has broken through the thin wall of stock material. This usually happens at the end of slots machining. This feature makes the exit safer without instantly going through the thin walls.

Expand the rest finishing area

This new parameter can be used to expand the rest finishing area boundaries to process more material and clean-up the remaining regions more efficiently.

2-Axis Machining

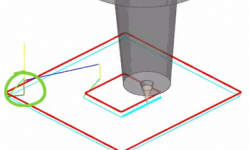

Start points for engraving and chamfering

This new option enables users to define unique start points for each contour to be machined. The toolpath start position is located at the shortest distance from the user defined start point.

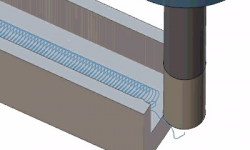

Lead-in and lead-out for engraving

Vertical profile lead-in and lead-out moves can now be used for engrave roughing and finishing operations.

Turning

New user interface for the turning component

The new, single-page interface for turning strategies is more intuitive and easier to use and speeds up the setup and selection process.

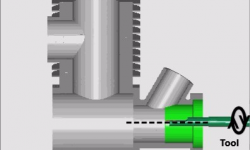

Internal grooving

This new feature enables users to add grooves to inner surfaces. It can be used with the turn roughing, grooving and profile patterns.

Simulation

Machine Simulator viewing area offers 4 separate views with independent and different orientations

This new feature enables users to simultaneously visualize the machine, the workpiece and the tool in different windows and from different perspectives to obtain an enhanced overview of the machining process and an instant and comprehensive visual analysis.

Cutting Simulator now supports facing head (facing slide) with planar toolpath input

The Cutting Simulator supports all processes, from very simple ones where the rotation is parallel to X, Y or Z, to arbitrarily placed rotation axes (not parallel to X,Y,Z) and any tool type and any toolpath direction.

RTCP status and shortest path settings

The status of the RTCP settings and the shortest path can make the difference between detecting a collision or not. These settings are important when the distance between two consecutive moves and angles provided for the simulation is too big. To enhance safety, this information is now displayed in the status bar of the Machine Simulator.

For further details about the 2017.12 release, see the ModuleWorks YouTube videos.

About ModuleWorks

ModuleWorks is a software component provider for the CAD/CAM industry. ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the CAM industry and its software components and development services are used by the majority of the leading CAM vendors for sophisticated industry focused solutions across diverse business sectors. ModuleWorks 5-Axis and Simulation software has been used in the manufacture of complex parts for over a decade and they have many users across the global CAD/CAM industry.