ModuleWorks announces the 2024.04 release of its software components. This latest release of the ModuleWorks SDK offers a range of new and enhanced functionalities for efficient, faster, and safer toolpath generation, ranging from improvements in 2-Axis Machining to Multi-Axis Surface Finishing and more.

Toolpath

Multi-Axis Roughing | Rotary Machining Roughing

Leads for Roughing

Challenge: For open regions, the toolpath often starts directly at the stock with a plunge movement, which may damage the tool or reduce tool life.

Solution: New lead-in/out options for rotary machining roughing toolpaths have been introduced. These additional motions ensure a smooth entry and exit of the tool into and out of the material.

Benefits: Users can now select the best way to engage the tool with the stock in the initial cut to avoid damage to the tool and minimize tool wear.

Multi-Axis Surface Finishing | Geodesic Machining

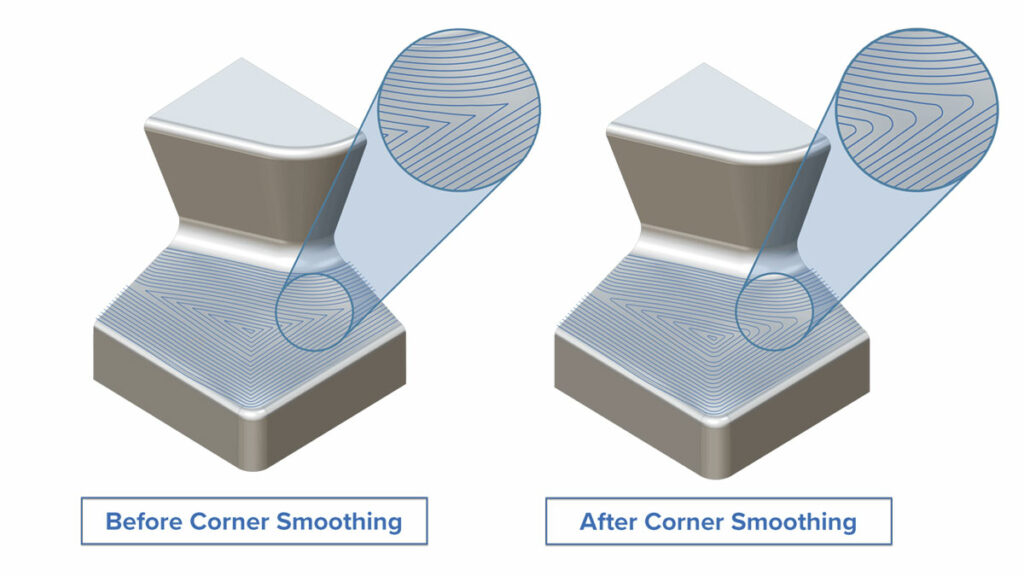

Improved Corner Smoothing

Challenge: In sharp corners, machining is typically slow as the tool has to decelerate significantly. This leads to longer machining times and poor surface quality.

Solution: The multi-axis geodesic machining strategy has been updated and now includes support for creating smooth corners in the toolpath.

Benefits: With corner smoothing:

– The overall machining time is reduced

– There’s no dwelling in corners and hence better surface quality is achieved

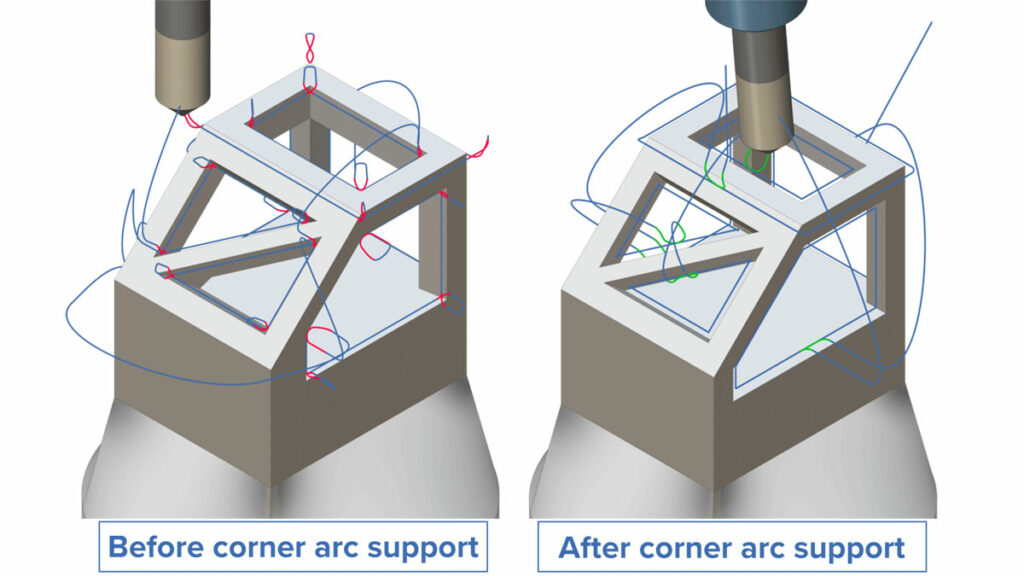

Multi-Axis Edge Finishing | Deburring

Corner Arc Support for Chamfer Tools

Challenge: The cutting motions in inner and outer corners are currently interrupted. The challenge is to produce uninterrupted cutting motions.

Solution: Enable the use of corner arcs for inner and outer corners.

Benefits: This reduces linking motions and machining time.

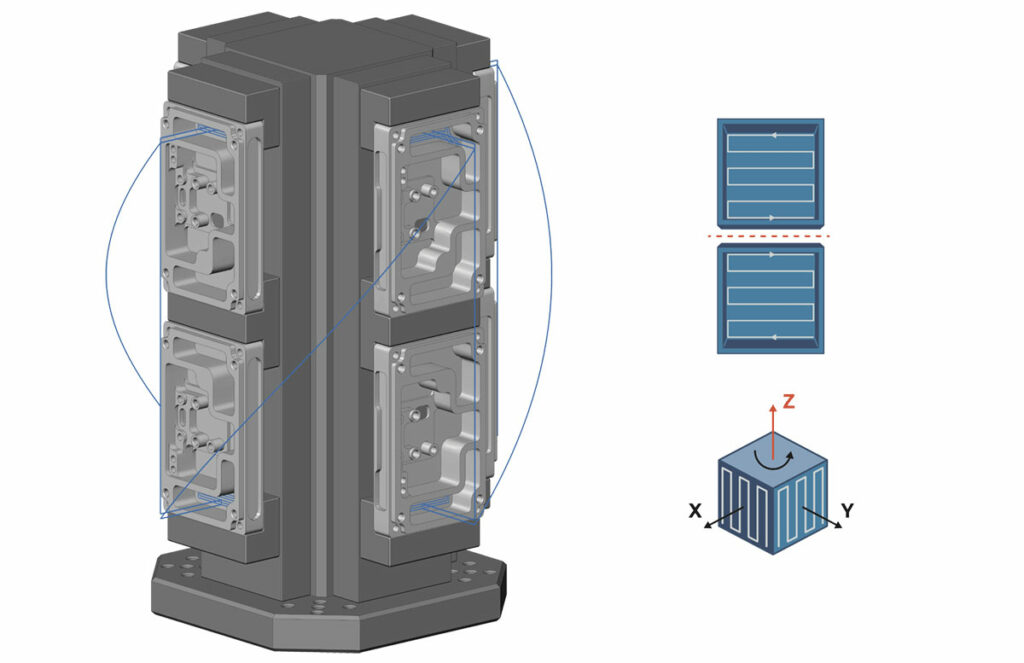

Convert | Existing Toolpath

Custom Rotate/Transform/Mirror Sequence

Challenge: Previously, there were limitations in tombstone machining where only one single operation could be rotated with a fixed order of rotation before any transformation was allowed and the mirroring operation was completely separate.

Solution: This new feature enables users to configure sequences for multiple transform, rotate, or mirror operations. The sequence is modeled in a tree structure which can be modified and clearance/link types can be determined based on transformation type.

Benefits: Real-world use cases can now be defined for tombstone machining to help users efficiently program a complete setup, thereby improving overall productivity. Linking moves are also generated according to the part orientation.

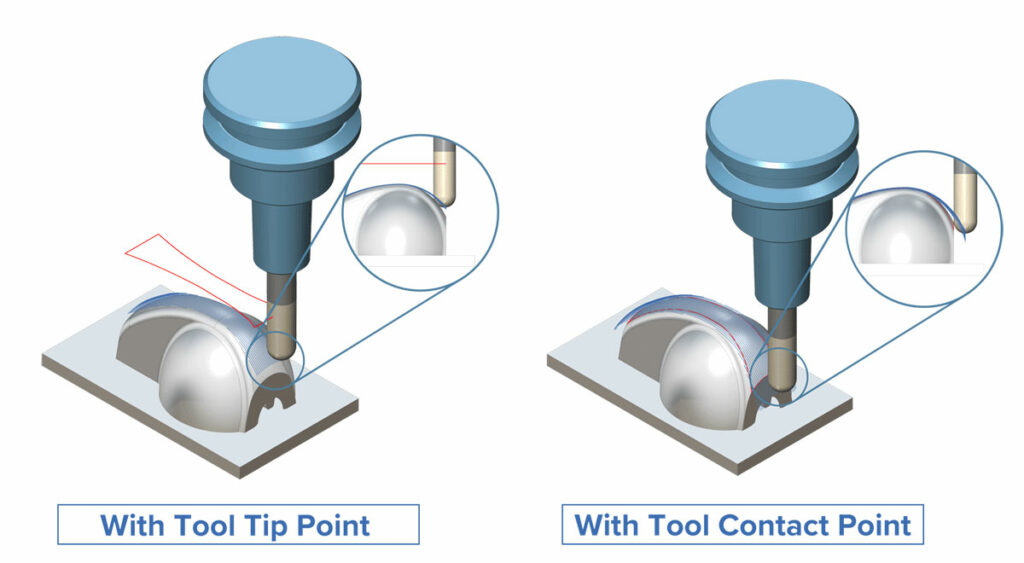

3-Axis Machining | 3-Axis

3D Contact Point Boundary for Finishing

Challenge: Current containment options limit the toolpath to the tooltip which can sometimes leave some areas unmachined.

Solution: The new 3D contact point boundary accurately limits the finishing toolpath to the 3D containment on the part to ensure the tool contacts the surface at all points regardless of the tool’s diameter or shape.

Benefits: This feature eliminates the need for users to recreate the containment or manually add offsets which reduces the programming time. It also ensures that the surface is completely machined.

3-Axis Machining | 3-Axis

Machine Flatlands after Each Slice

Challenge: Currently, deep pockets are not reachable by tools (with DHC and Flatland activated) in some cases during roughing because of the in-process stock on top slices.

Solution: The new enhancement adds the ability to machine flat areas after each main slice instead of machining after the last slice.

Benefits: Deeper pockets can be machined together with flatlands with an optimal tool length (outside holder).

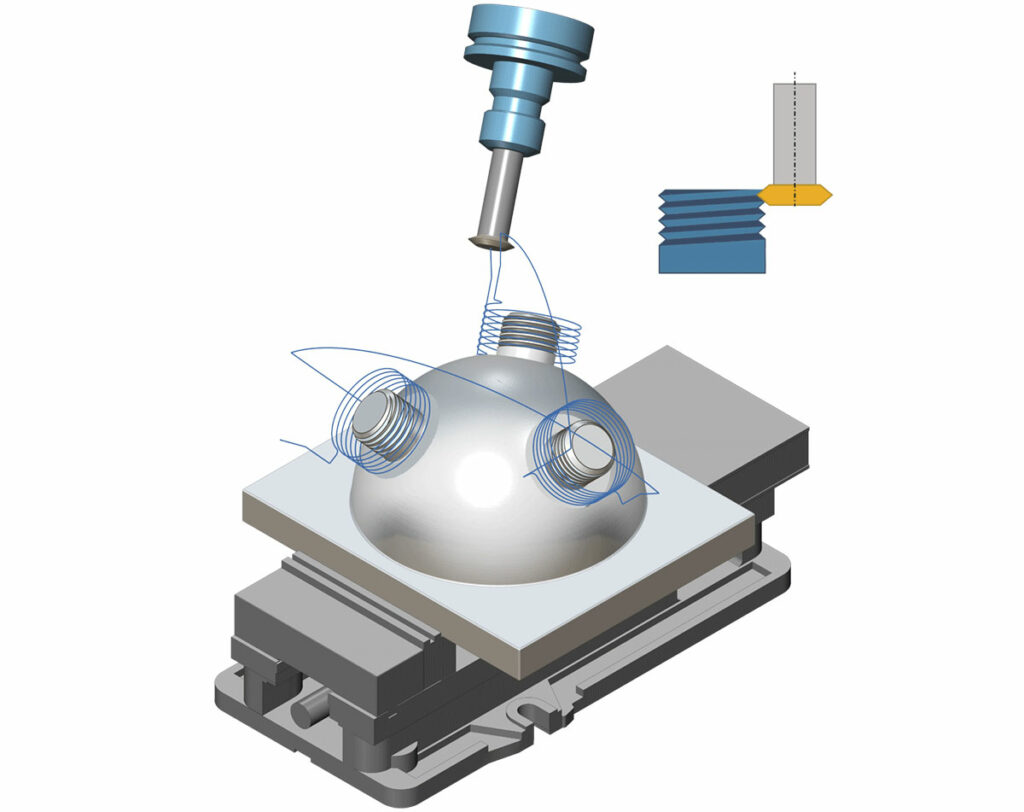

2-Axis Machining | Hole Making

External Thread Milling

Challenge: Machining external threads on hard materials is very difficult in today’s world.

Solution: A new strategy is introduced for external thread milling.

Benefits: The new strategy for external thread milling provides benefits such as the ability to machine threads on difficult-to-cut materials, and using the same tool for multiple thread diameters. In many cases, external thread milling is the only viable option when the part geometry or shape is complex and external threading is not possible on the turning center.

There are many other new enhancements in this release.