Wall, Floor and Rest Finishing

Produce High-Quality Parts Faster Using 5-Axis Finishing Toolpaths from Moduleworks

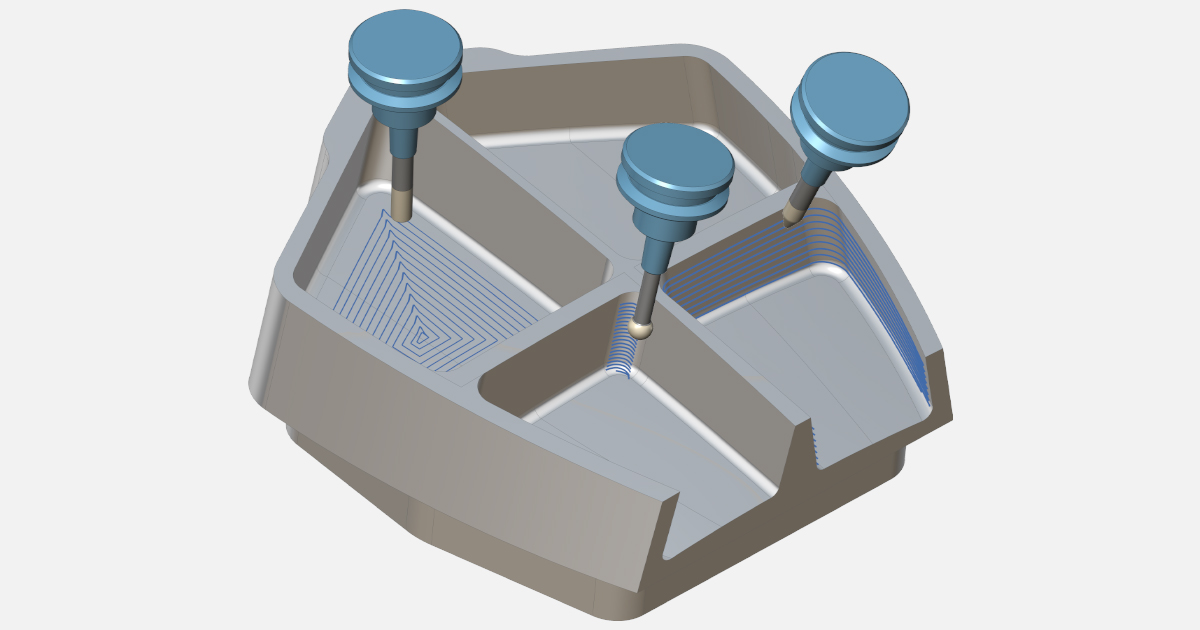

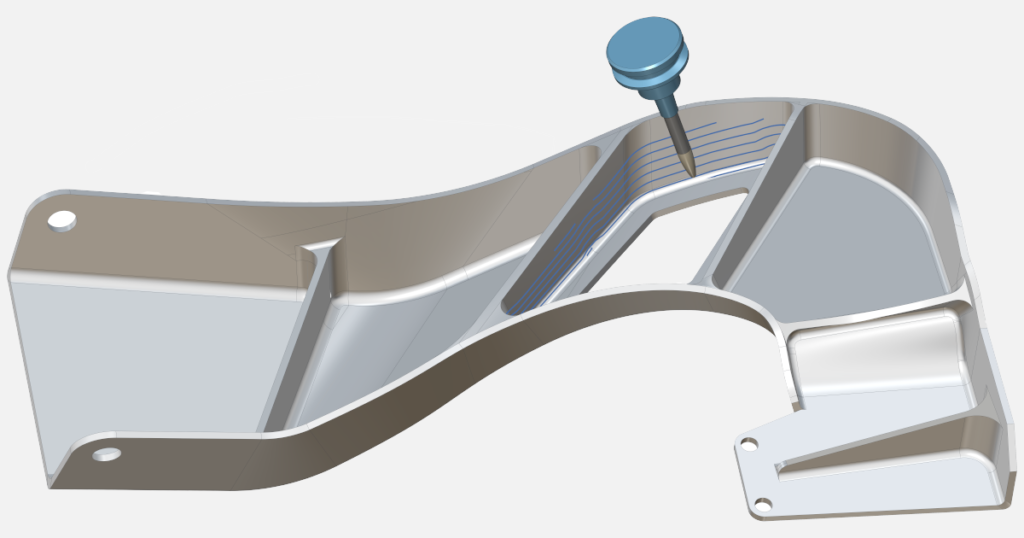

ModuleWorks Wall, Floor and Rest Finishing product is an advanced, industry-proven CAD/CAM software component for finishing simple to complex parts in multi-axis. It integrates rapidly and seamlessly in third-party environments primarily CAD/CAM systems. Combined Wall, Floor and Rest Finishing in Multi-Axis Surface Finishing toolpaths refers to an integrated approach to machining that ensures the entire surface of a part including wall, floor, and any remaining areas not fully finished in previous operation can be completely machined.

Major Challenges

Achieving High Surface Finish for Complex Parts

Multi-axis surface finishing requires precise machining to achieve the required surface quality and finish. This is often difficult due to the part/geometry complexity.

Avoiding Collisions

During multi-axis machining, there is often a risk of collision for the tool or holder due to complex machine kinematics and intricate part profile. This needs to be assessed to ensure safe machining.

Higher Machining Costs

5-axis machine tools are costly and so is the labor that operates these complex machine tools. Less optimized finishing process can result in higher machining costs.

Solution Offered by ModuleWorks

ModuleWorks Wall, Floor and Rest Finishing combines powerful algorithms for fast generation of high-quality 5-axis finishing toolpaths. It empowers users to easily create 5-axis operations on individual features of production parts with advanced tilt settings and advanced tools like barrel tools.

Key Highlights

Highly Efficient Due to Optimized Pattern

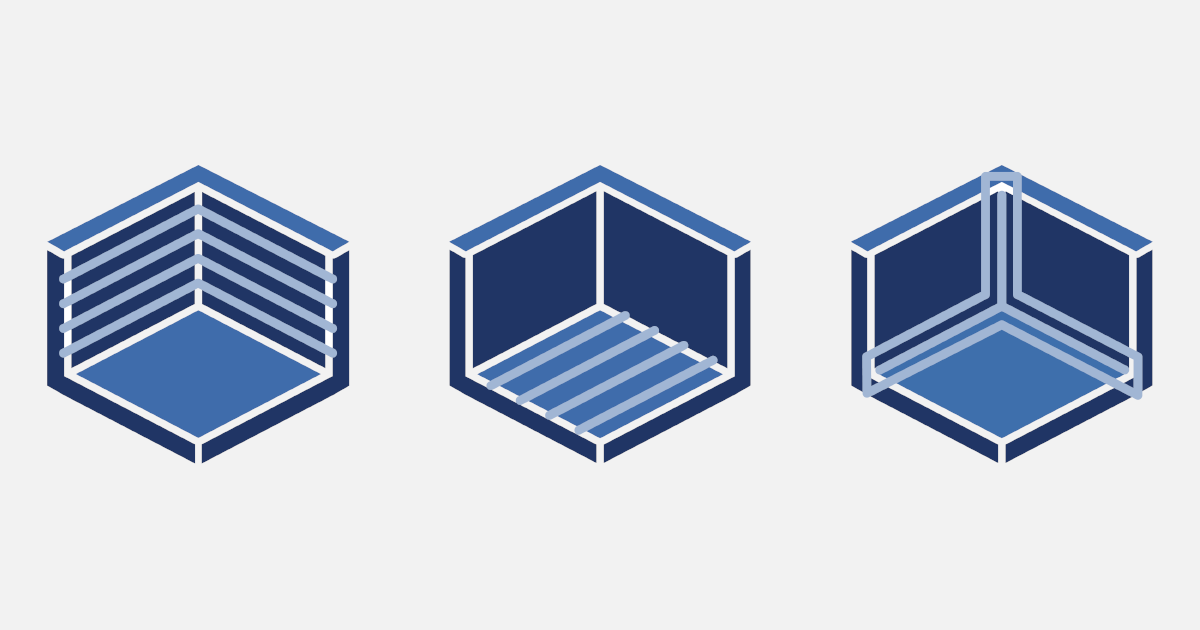

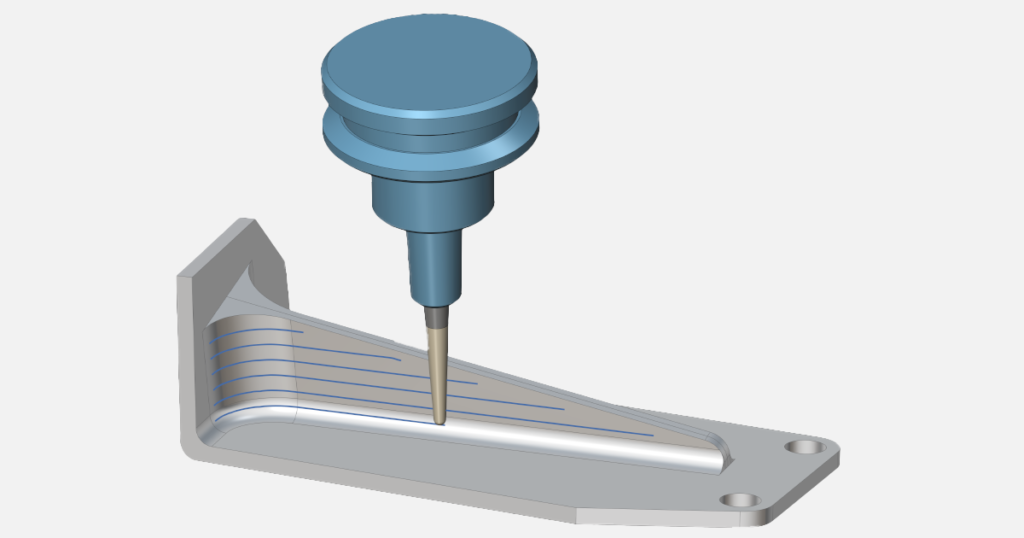

Wall Finishing

Machine vertical or near-vertical surfaces to produce smooth and accurate vertical walls. Supports parallel pattern to ceiling, floor boundary, or user-defined curve. Morphing patterns can also be generated between ceiling and floor boundaries.

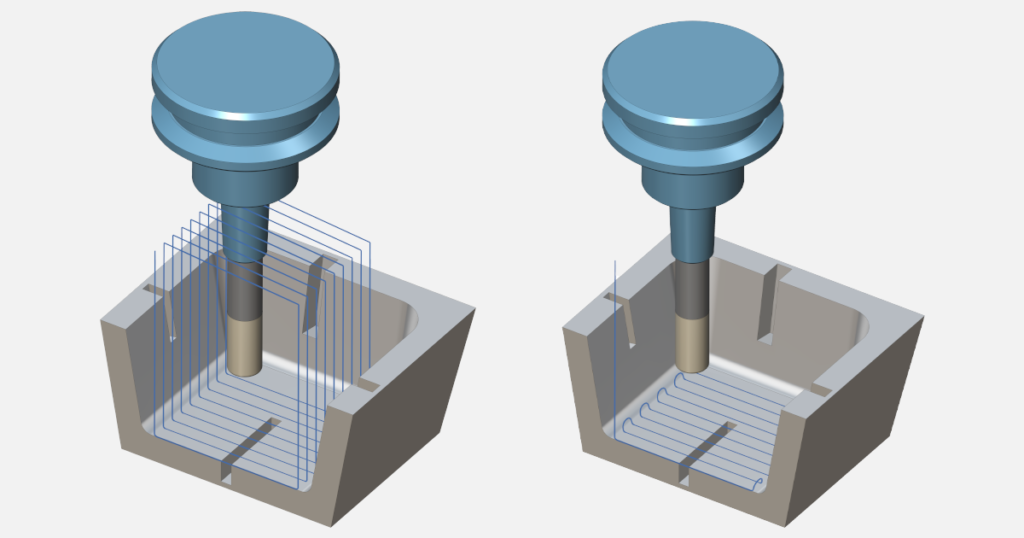

Floor Finishing

Machine horizontal or near-horizontal surfaces to achieve a smooth surface finish on the floors. Both offset pattern and parallel pattern can be generated.

Rest Finishing

Machine leftover material not finished in previous operations to fully finish the part. Either medial axis or floor boundary can be used for rest finishing pattern calculation.

Automated Tool Axis Control

Key Benefits

Achieve excellent surface finish with modern tools and reduce rejections/rework

Simplify programming complexity using automated technology that requires minimum user input

Simulate and verify the toolpath before executing on machine for maximum safety and reliability