Laser Surface Treatment

Automatic and Efficient Laser Surface Treatment Software Technology from ModuleWorks

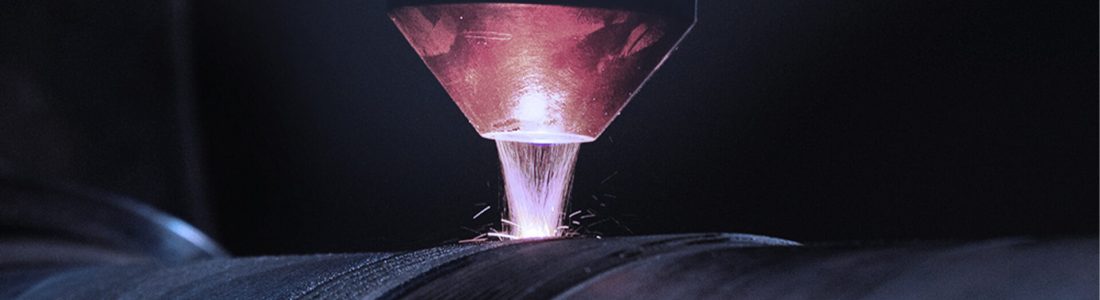

Laser Surface Treatment is an industry-proven solution for CAD/CAM software integration, inline processes, machine tool builders, and robot OEMs or integrator organizations. It offers the most advanced features and functionalities, including collision avoidance, reduction of overlaps to prevent duplicate treatment in specific areas, and achieving consistent hardness across all points. It also supports processes like Remote Laser Hardening, Laser Coating, and sensor and scanner integrated solutions.

Major Challenges

Manual Control

The manual process makes it more challenging to maintain consistency quality at each path point. Operators often manually adjust the laser parameters, such as laser power, speed, and spot width for each specific area. The main goal of the software package is to avoid manual interaction or teaching since this can lead to variations in the hardness and quality of the treated surface.

Complex Part Geometries

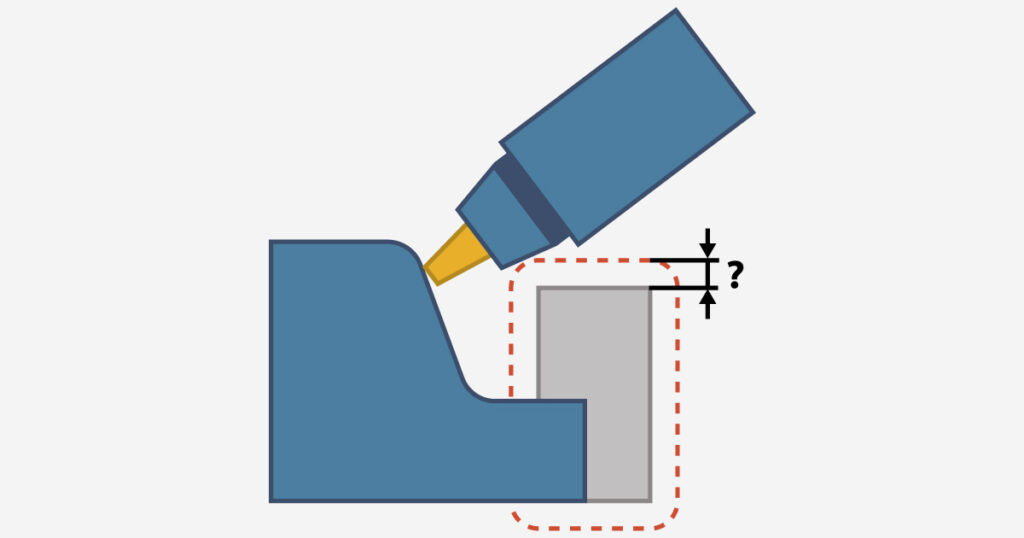

Programming complex parts for Laser Surface Treatment involves significant challenges. In industrial state-of-the-art processes, it is very often required to manually adjust the toolpath coordinates, and reorient the laser nozzle for each specific area of the part.

Collision Avoidance

Ensuring collision-free operation is a significant challenge due to the poor quality of available CAD data, and the absence of simulation tools.

Solution Offered by ModuleWorks

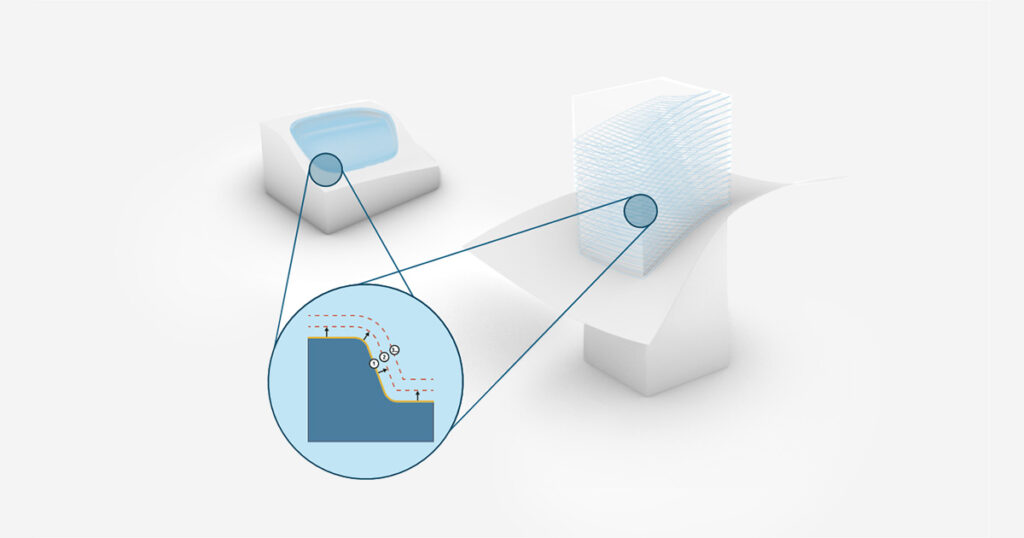

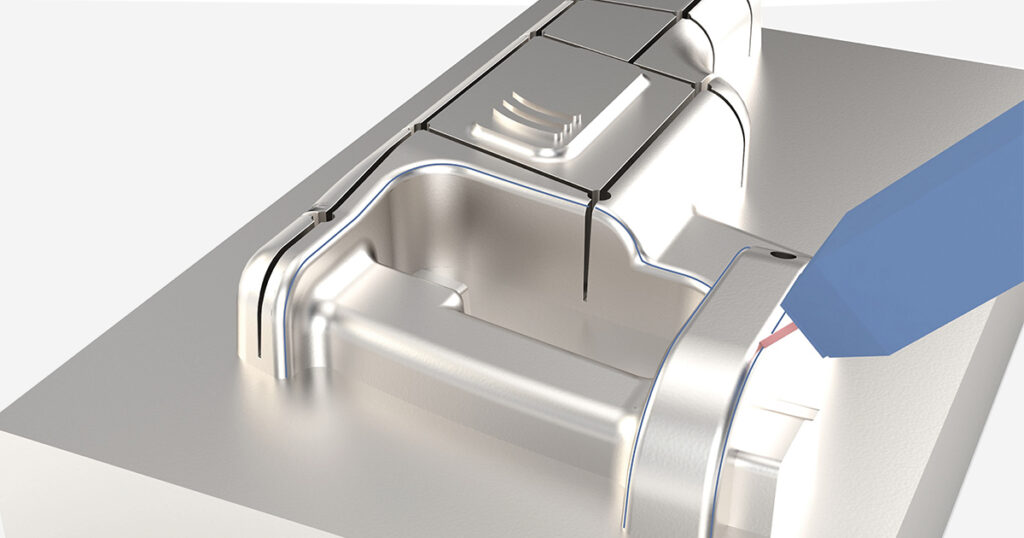

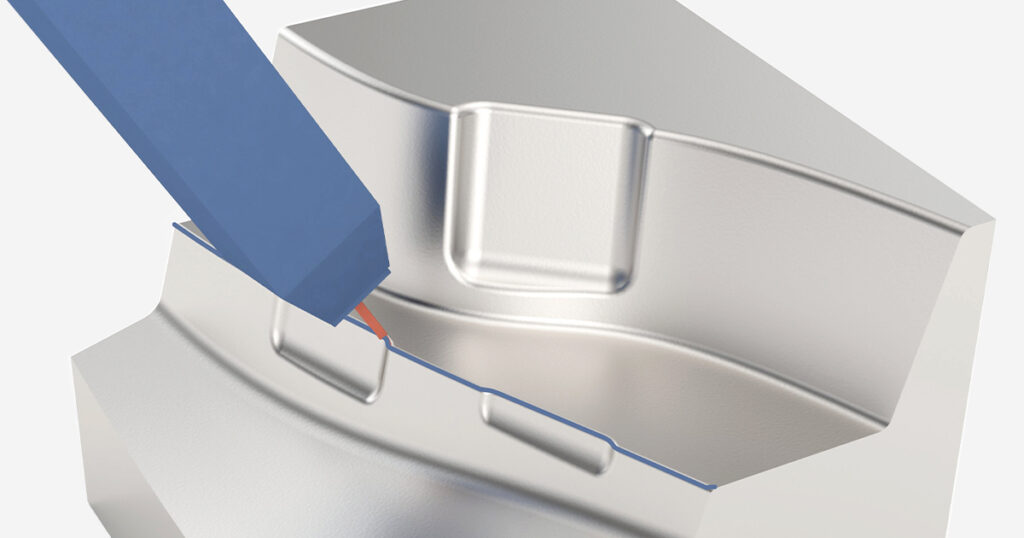

ModuleWorks offers advanced toolpath calculations for machine tools, featuring process-specific parameters like single and multi-slice toolpaths, beam width, penetration control, and automatic collision avoidance.

Key Features

Key Highlights

Advanced Toolpath Generation for Complex Geometries

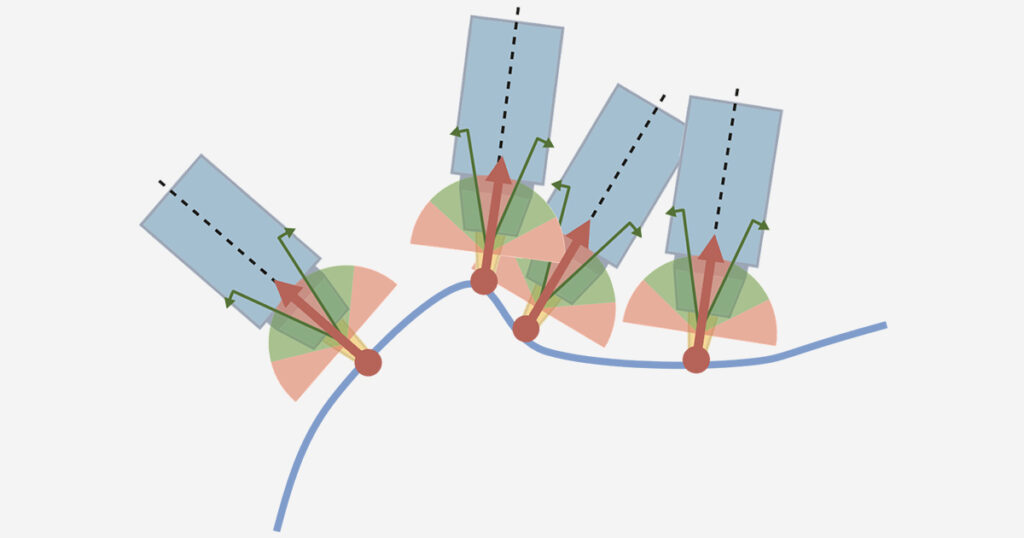

This solution supports 6-axis toolpath calculations, which are crucial for the Laser Surface Treatment process. Properly defining the orientation of the 6-axes ensures the laser is guided at the optimal angle to the heat source.

The pattern is defined from a guide curve, or a drive surface (mesh), and all laser slices are created as 3D-equidistant paths from that contour. Various options allow precise control over the toolpath. Additional options like support for the constant distance between the laser slices, lead/lag angles or side tilt angles, full collision avoidance, and multi-layer laser toolpaths ensure optimal toolpath generation.

Proven ModuleWorks Technology

Proven ModuleWorks Technology: ModuleWorks Laser Surface Treatment technology was developed through extensive research and collaboration with leading industrial partners. This technology has successfully addressed real-world challenges in various production environments. It has established itself as a reliable and effective solution. ModuleWorks can also support different devices and remote scanner systems.

Key Benefits

Easy manufacturing of complex parts due to precise control of parameters within easy-to-use UI

Improved productivity and surface quality due to automatic and efficient path calculation

Safe machining process due to collision-free toolpath calculations

Integrating additive feature creation, coating, and laser hardening offers a versatile solution for combined surface treatment