Simulation SDK

Faster and Accurate Simulation of the Manufacturing Processes with Moduleworks Simulation SDK

There is a wide variety of additive and subtractive manufacturing processes used in the industry. There is a need to back it up with fast and accurate virtual representation of these processes. Whether it be subtractive manufacturing processes such as Milling, Turning, Wire EDM or additive manufacturing process such Wire Arc Additive Manufacturing, verification of these manufacturing processes in a virtual environment to mitigate the risk related to failure in the process is required. ModuleWorks has developed a solution for verification of the manufacturing processes involving 2,3 and 5-axis machining, multi-turret, robotic applications for all CAM software developers, machine tool builders and CNC controller manufacturers.

Major Challenges

Early Mitigation of the Process Risk

Unless the manufacturing process (additive or subtractive) is evaluated for several failure modes, it is hard to control the process variables and results in unexpected breakdowns.

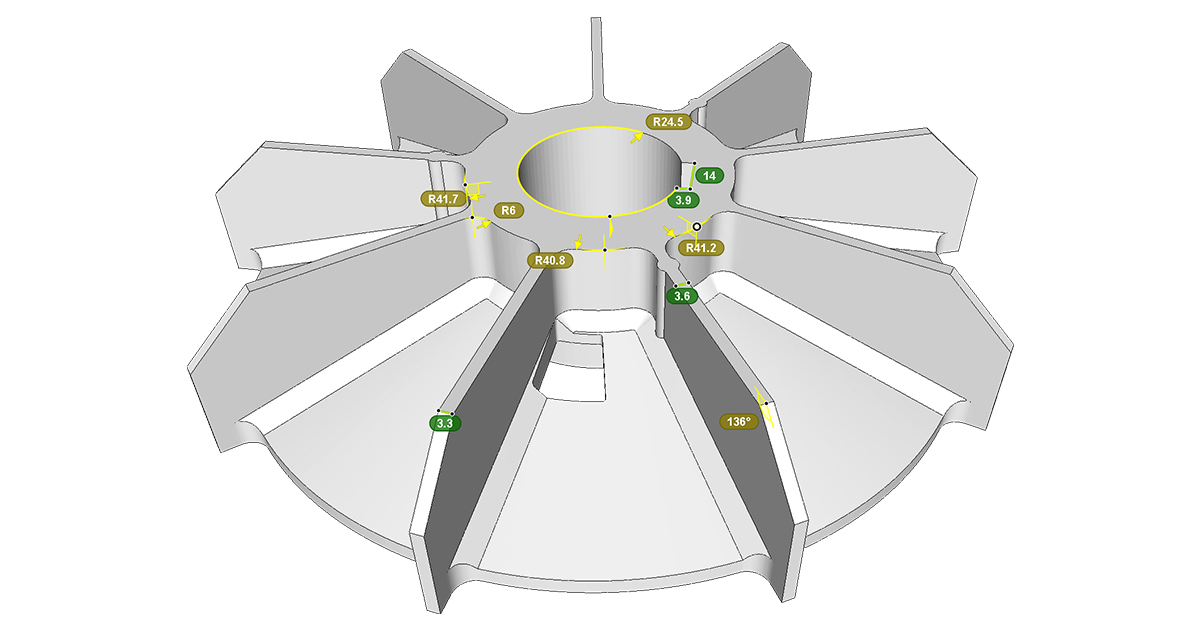

Micro Analysis

Toolpath verification on smaller segments or 3D slices is more important when working on undercuts/unapproachable areas. However, this becomes difficult in absence of simulation and analysis tools.

Collision Avoidance

Historically, collision avoidance for manufacturing process is of utmost importance since it holds higher risk of damage to the machine tool/fixture/workpiece. Evaluation and prior prohibition of collision with multiple components is difficult with traditional methods.

Time to Market

In absence of simulation of the manufacturing process, actual manufacturing trial needs to be conducted to validate the process. This involves additional time and cost and also increases time to market.

Solution Offered by ModuleWorks

ModuleWorks Simulation SDK offers a highly capable API which can be seamlessly integrated into CAD-CAM software’s, and on modern day CNC controllers to simulate the toolpath. It uses machine axis values calculated from a virtual origin and thus relative motion between tool and workpiece is simulated on a CNC controller, or on CAD CAM software.

Key Highlights

Machine Simulation (CNC Sim)

The CNC Simulator is a software component for CNC kinematics simulation. It can be integrated directly onto the Human Machine Interface (HMI) or CNC control to provide material removal simulation, toolpath analysis and support for all operating modes. Look-ahead axis data calculated from the CNC controller enables in-time collision avoidance.

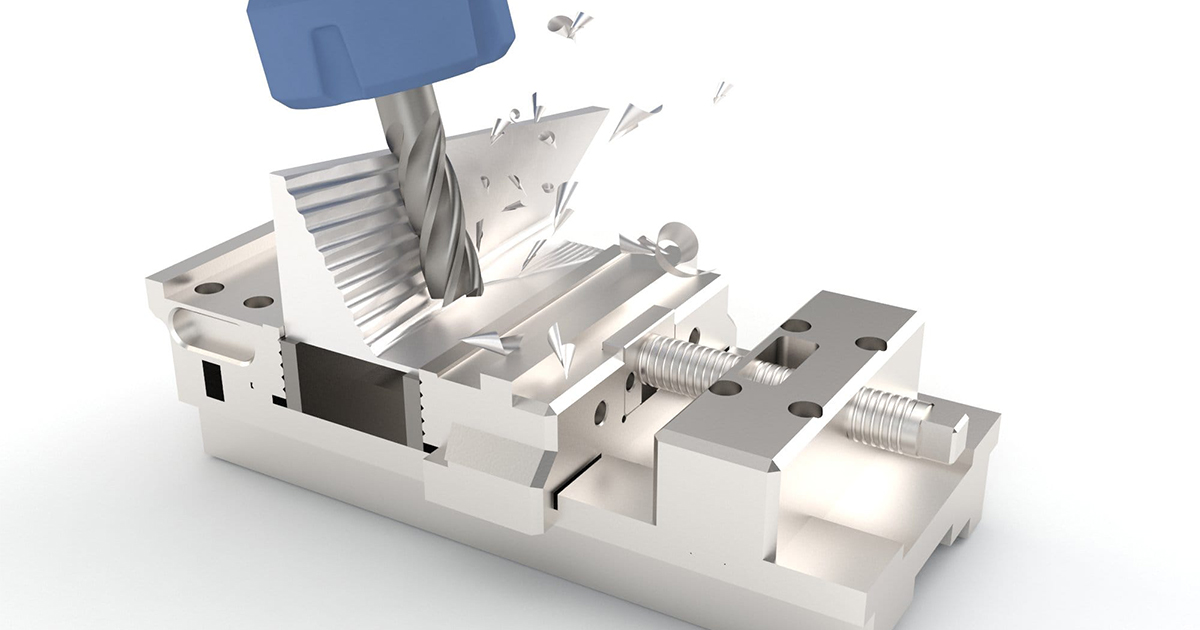

Cutting Simulation (Cut Sim)

The cutting simulation component provides fast, high-accuracy verification of stock removal for milling, turning, and combined mill-turn applications, plus a full range of toolpath behaviour analysis tools for segment length/type, feed rate and height allowing toolpaths to be refined for optimum finish and quality.

Key Benefits

Accurate and faster verification of the manufacturing process ensuring safety

Detailed reports highlighting collisions and other issues ensuring a thorough understanding of the manufacturing process

Precise stock removal simulation contributing to the reliability of the overall process