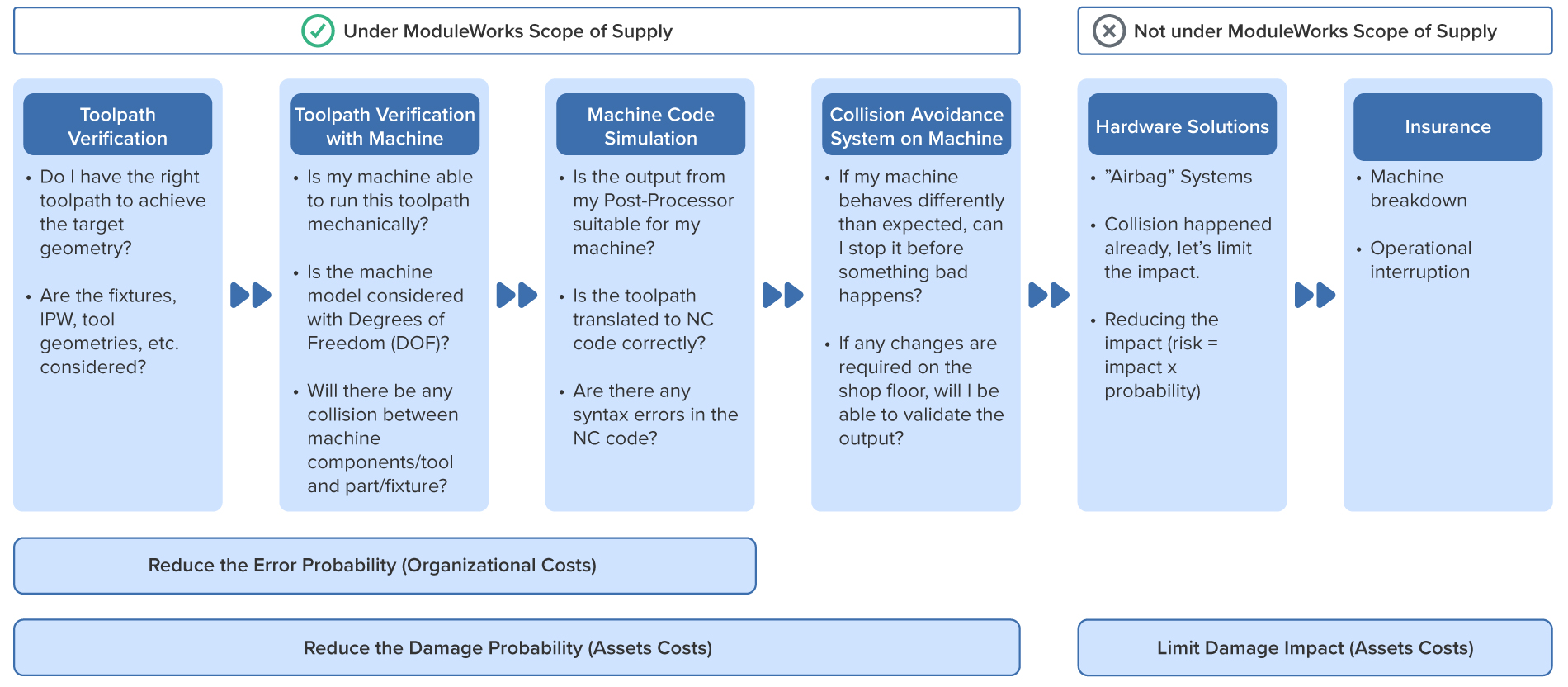

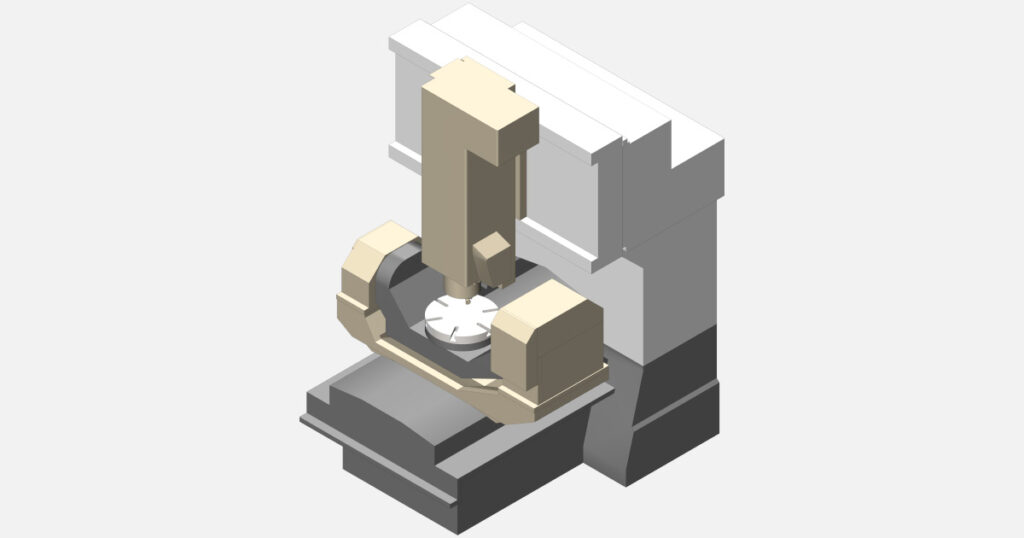

Creating CAM programs can be difficult sometimes. Manufacturers always want to ensure that the CNC programs run safely on their machines without any surprises. However, this is not always the case. More often than not, machine operators find themselves having to modify CNC programs because the machine exceeded its limits, or a specific code didn’t work as expected. Machine Simulation is crucial here, as it provides users with an accurate representation of the machine’s behavior when running toolpaths and, ultimately, the output NC code.

ModuleWorks provides an advanced and robust portfolio of simulation products that address the end-to-end simulation requirements of the manufacturers. Our Simulation portfolio primarily addresses organizations seeking to deliver software solutions for simulating discrete manufacturing processes. With its two product lines, Simulation SDK and Simulation Systems, it enables CAM software developers, CNC controller manufacturers, and Machine Tool Builders to allow an integrated toolpath and NC program verification using state-of-the-art simulation technologies for their end users.

Typical Business Challenges

Optimizing the Process

Avoiding Collision

Reducing Cycle Time

Providing Proven Technology

Solution Offered by ModuleWorks

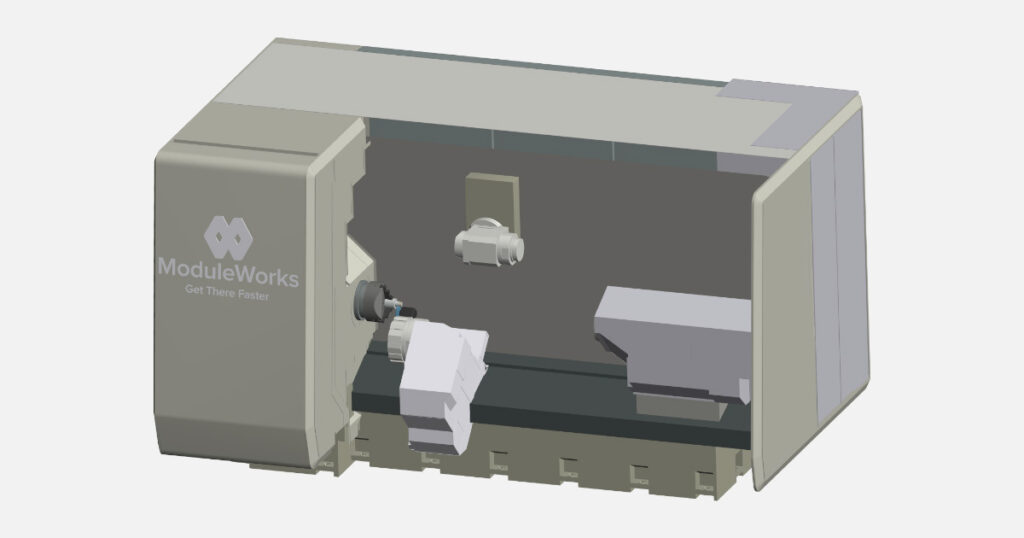

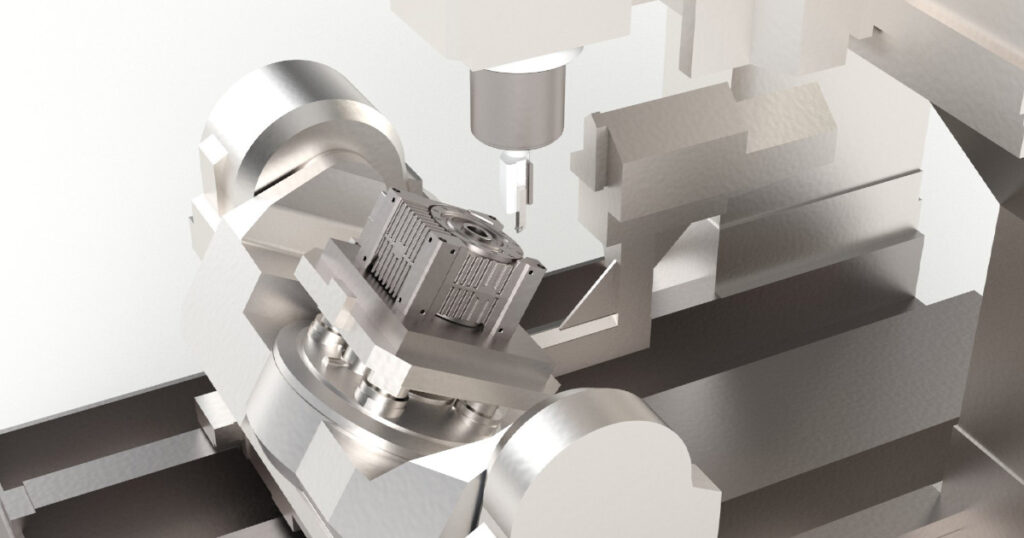

ModuleWorks Simulation portfolio provides full kinematic simulation with collision checking and material removal/additive simulation with scalable performance and usability. These technologies allow our partners to accurately simulate machining processes with machine movements and analyze them for errors and optimization potential in their software solutions.

The simulation components support Microsoft Windows-based desktop systems as well as Linux-based machine controllers located on the machine tool (depending on your hardware and software requirements). CNC simulation tools are independent of our toolpath generation components and can be used with any toolpaths or backplot NC code.

The technology can be easily integrated into either a CAM software or directly on a CNC controller for seamless and efficient verification of toolpath or NC-code. On-machine simulation offers several benefits and an additional layer of safety before running the programs on a machine.

Comprehensive Support for Various Manufacturing Processes

Solutions Available in ModuleWorks Simulation Portfolio

Simulation SDK

The Simulation SDK consists of software components that enable solution providers to rapidly build and seamlessly integrate state-of-the-art simulation technology into their existing software solutions via programmable interfaces (APIs). These components allow tailor-made workflows, ensure seamless user experience, and maximize the fit-to-market of our partner’s solutions.

- Single SDK that covers all simulation needs

- Stable and efficient components with wide industrial adoption

- Can be fully integrated into existing software solutions to offer a seamless user experience

- Best possible interoperability with ModuleWorks Toolpath SDK

Simulation Systems

In contrast to Simulation SDK, to facilitate the lowest effort-to-market, our Simulation Systems product line provides multiple ready-to-go software systems that our partners can rebrand to market typical simulation solutions in the fastest way.

- Extensive product line with technologies ranging from standard machine simulation to collision avoidance system and beyond.

- Possibility to simulate both subtractive as well as additive manufacturing processes

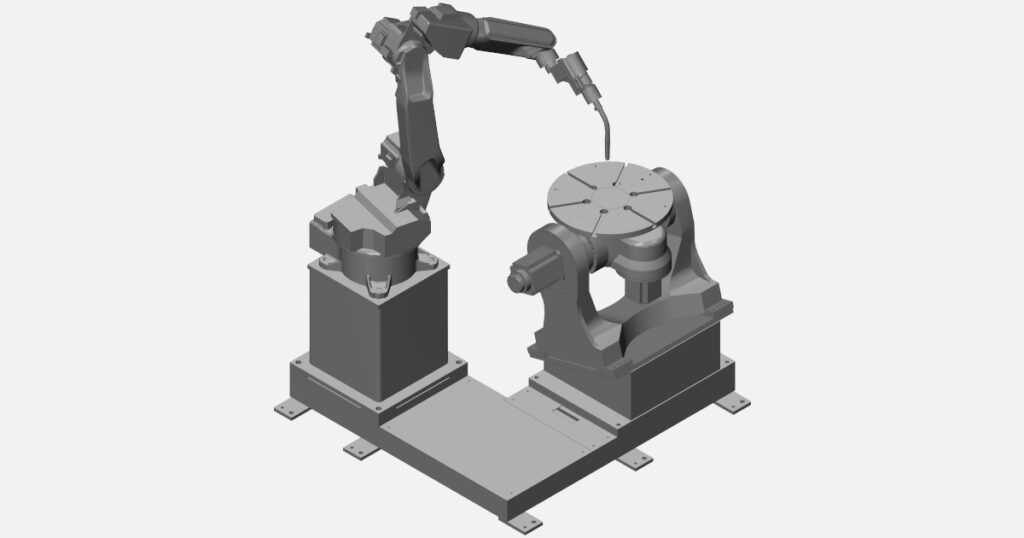

- Wide range of supported machine types and kinematics

- Tried and tested technologies used with vast majority of CAM software and CNC controllers in the industry today

Why ModuleWorks Simulation?

Proven Market Leading Solution

Our Trusted Partners

Key Benefits

Simulate the entire process accurately before executing it on real machines

Broad coverage of widespread and upcoming manufacturing processes

Dedication to performance excellence (e.g., GPU accelerated Simulation)

Powerful analysis tools to generate insights and enable feedback loops

Efficient support of diverse hardware and software platforms

Reliable technology, as proven by various integrations in CAM software and embedded systems such as CNC Controls