ModuleWorks announces the 2025.04 release of its software components for digital manufacturing. This latest release of the ModuleWorks SDK includes new and enhanced features designed to enhance process safety, improve toolpath generation efficiency, and increase part quality.

Multi-Axis Edge Finishing - Deburring

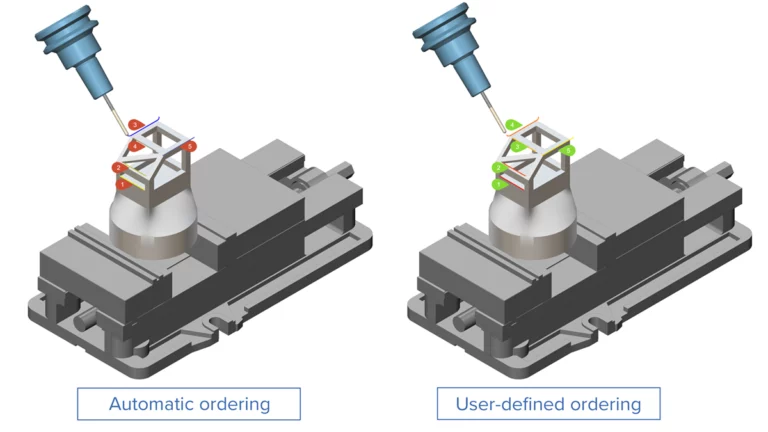

User-Defined Edge Sequence

With automatic sorting, it is often difficult to meet the deburring requirements of each part because the predefined order does not always match the specific needs of the job.

The ModuleWorks 2025.04 release introduces a practical alternative to automatic sorting: Users can now preserve the input order of the curves, and the resulting toolpath is sorted accordingly. This gives users more flexibility, enabling them to machine edges in their preferred sequence to improve overall machining efficiency and precision.

Multi-Axis Edge Finishing - Deburring

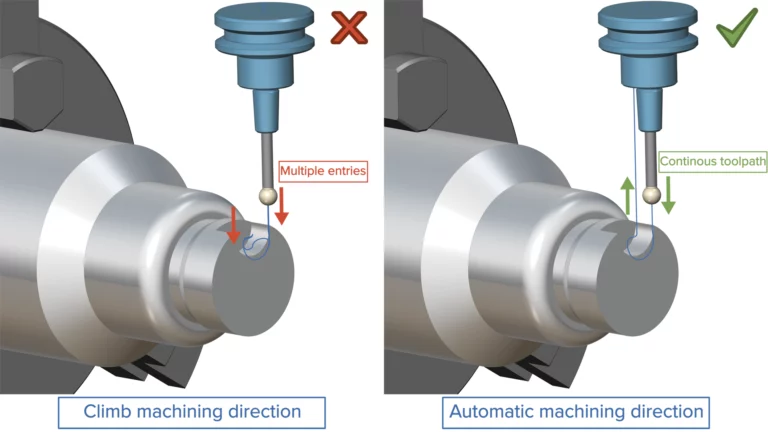

Automatic Machining Direction

Previously, determining the appropriate machining direction for 3- and 4-axis toolpaths often led to suboptimal ordering, resulting in discontinuous toolpaths.

ModuleWorks 2025.04 contains a new option called ‘automatic machining direction’ that takes the contour direction into account to ensure optimal ordering. This makes deburring toolpaths more user-friendly while also reducing the machining cycle time.

Special Parts - Multiblade

Edge Finishing

Users often struggle to prevent the tool from rubbing against the leading edge due to tilting and machine motion. Since the edge is thin, this may cause it to overheat.

ModuleWorks 2025.04 solves this problem by applying an extension, leaving offset material to be removed later. This strategy drives the tool longitudinally along the edge, effectively removing the extra material leftover from the previous operation without causing damage to the thin leading edge. This enhanced toolpath allows the part to be finished with the required surface quality and material integrity.

3-Axis Machining

Corner Peg Removal for Constant Cusp

Generating a consistent surface finish in corner regions is often hampered by pattern collapse and corner smoothing.

The ModuleWorks 2025.04 release introduces an intelligent Corner Peg Removal solution that tackles problematic cusps where the pattern collapses or corner smoothing shifts the toolpath. This new approach automatically adds strategic peg loops in corner areas, ensuring smooth, consistent results and minimizing the need for manual polishing.

Simulation SDK – Cutting Simulation

GPU-Accelerated Collision Checking

Simulating material removal while checking for potential tool collisions with the in-process stock is computationally intensive, causing the simulation to slow down in complex machining scenarios.

The ModuleWorks 2025.04 release offers enhanced simulation capabilities through GPU-accelerated simulation, which can now be used to optimize both material removal and collision checking. This feature increases the simulation speed, particularly for large-scale machining operations, while ensuring precise collision detection.

ModuleWorks 2025.04 is available for download from the ModuleWorks website.

For more details about these and the other new features and enhancements in the ModuleWorks 2025.04 release, see the ModuleWorks What’s New webpage: What’s New in ModuleWorks 2025.04.

About ModuleWorks

ModuleWorks is at the forefront of digital manufacturing software, playing a key role in enabling the efficient production of increasingly complex parts in an environmentally sustainable way. As a strategic partner to leading CAD/CAM vendors, CNC control makers, machine tool builders and cutting tool manufacturers, ModuleWorks develops software that powers solutions throughout the manufacturing industry which contributes to 16% of global GDP worth $16 trillion per year.

Founded in 2003, ModuleWorks has grown to over 200 employees and already invested 1,700 person-years of software development in toolpath and simulation technologies that form the core of manufacturing processes. In the CAD/CAM area alone, ModuleWorks has a market share of 90%, enhancing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software worldwide.With a comprehensive portfolio of cutting-edge software components and the capacity to address emerging and niche technologies like AI, cloud, automation, additive, robotics and digital dentistry, ModuleWorks is committed to shaping the future of digital manufacturing with its partners, empowering the industry to Get There Faster.