ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, has announced the latest release of its CAM components, ModuleWorks 2015.08, the second major update of 2015. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version includes new features for 5-Axis, 3-Axis, Port Machining and Simulation.

ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today.

Highlights of the new release are shown below:

4-Axis Rotary Machining

| ModuleWorks 2015.08 includes a new Rotary Machining Module. The new option is specifically designed to generate 4-Axis rotary roughing toolpaths on STL meshes for parts such as compressor screws, extruders or other complex rotational geometries. Ease of use is a key feature with the toolpath created by simply specifying the target and stock geometry. The toolpath offers full collision control and safe linking. |  Rotary-Roughing (constant radius) Rotary-Roughing (constant radius) |

5-Axis Machining

|

The transform capability has been extended with the introduction of Mirror capability. This allows a mirror image of a toolpath to be easily created about a user defined axis and point. This is particularly useful where both left- and right-sided parts are required. |

Symmetrical toolpath mirroring |

|

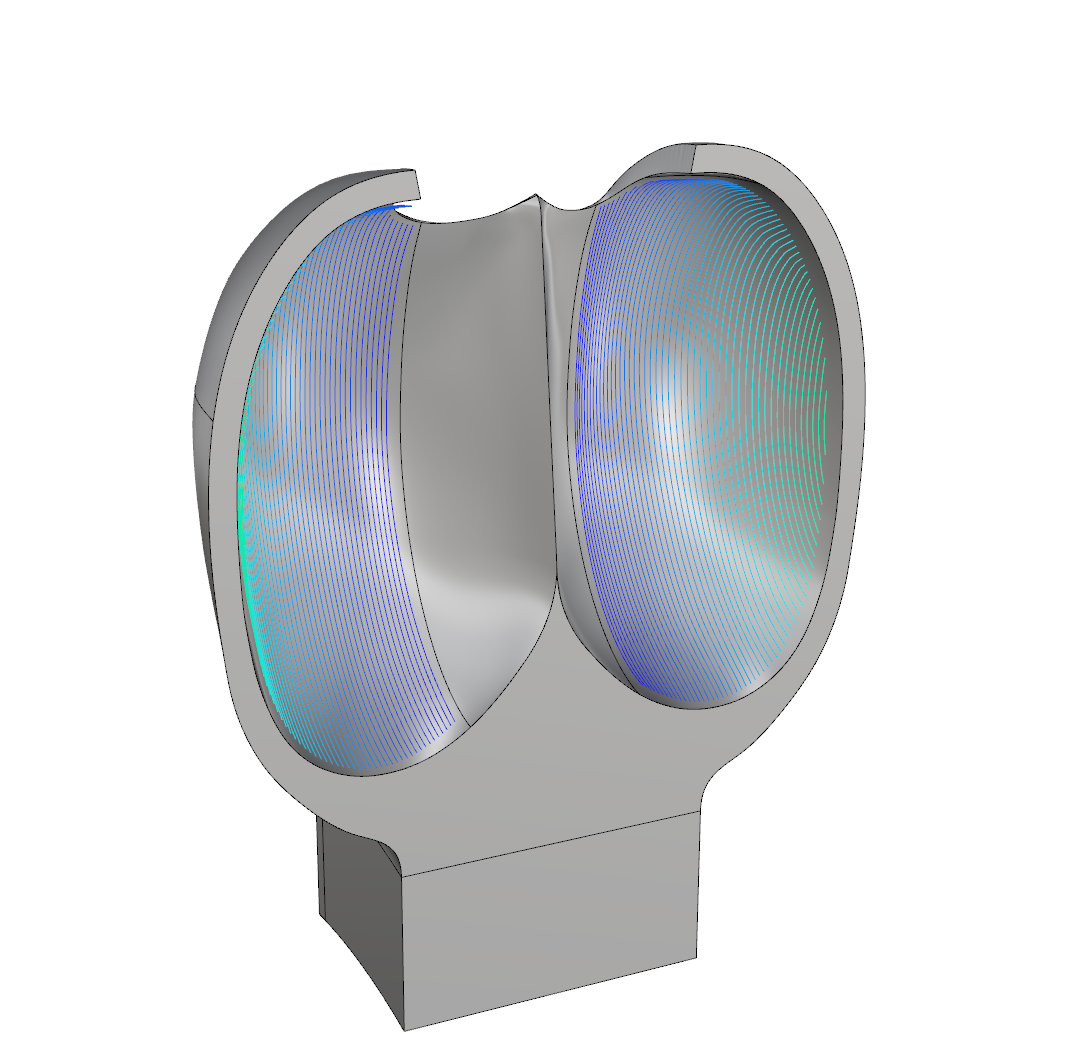

A new 5-Axis Surface Flow Line is now available. The resultant toolpath is mapped along the U or V direction of the single target surface to provide a smooth toolpath with excellent surface finish. Additional collision checking controls have been added and a new option has been added that will avoid collisions by retracting the tool in the selected tool plane. Motion is orthogonal to the cutting direction and independent from the target geometry to ensure safe motion. |

3-Axis Machining

ModuleWorks 3-Axis STL mesh-based toolpaths now offer an inbuilt machining template capability to define default parameters. This functionality no longer needs to be developed by the integrator, so implementation is now easier and faster.

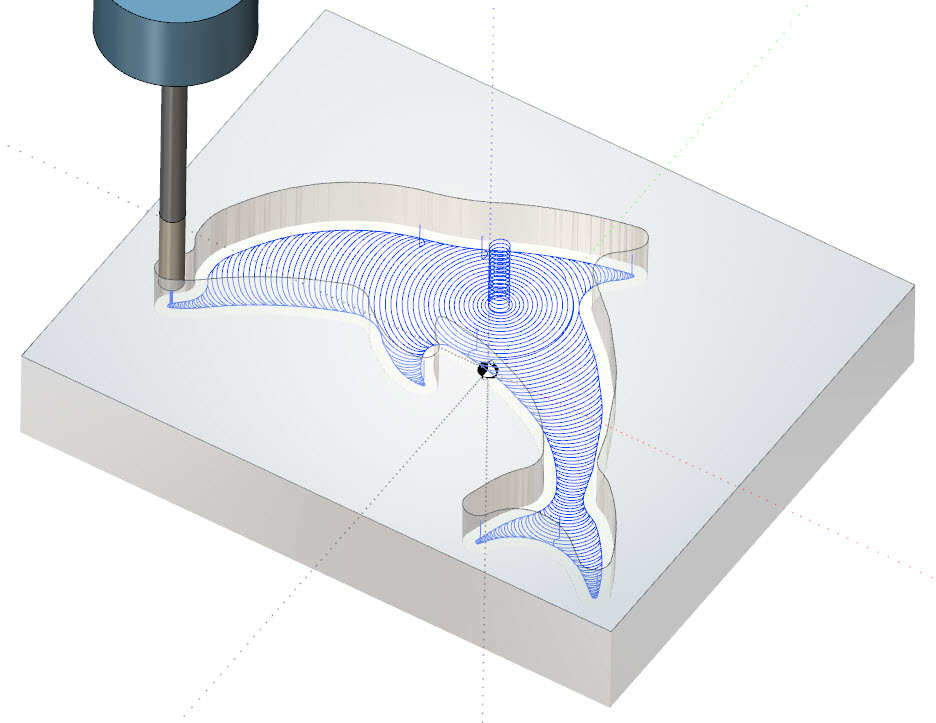

| The adaptive roughing toolpath has significant improvements to toolpath control, quality and performance. Enhanced controls are available for stepdown motion, smoother leads and 30% + faster calculation time. 2.5D machining now allows a pocket boss structure to be defined using wire frame geometry. Heights are considered, making it easier to machine the target geometry using fewer steps. Finish profiling now supports cutter compensation making for easier to read NC code. |

Adaptive Roughing Adaptive Roughing |

Simulation

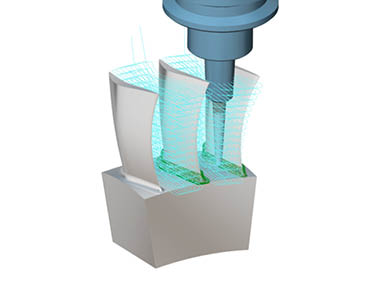

The progress bars and color representation for collision and proximity indication have been revised, making them more informative and easier to understand. Other aesthetic improvements include a redesigned feature to overlay toolpaths in the simulation.

| Simulation now offers the integrator the option to specify the color used by a group of different operations. The toolpath and material removal for these operations will use the specified color. |  Operation-based group color Operation-based group color |

The 2015.08 release is now available to all partners from the customer download area at www.ModuleWorks.com