ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, has announced the latest release of its CAM components, ModuleWorks 2015.04, the first major update of 2015. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version includes new features for 5-Axis, 3-Axis, Port Machining and Simulation.

ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today.

Highlights of the new release are shown below:

5-Axis

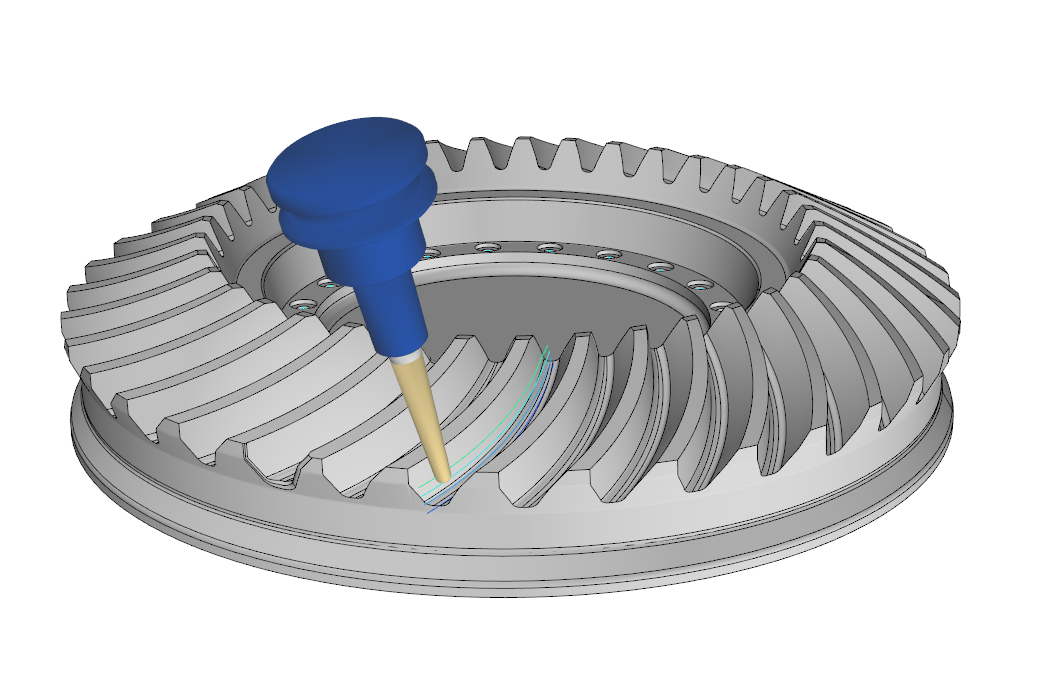

ModuleWorks SWARF now offers a new stripe milling feature which allows the user to create multiple intermediate slices following the part shape. This allows SWARF strategies to be used for machining convex type shapes such as gear flanks and the pressure sides from impellers. A best fit option ensures optimum tool axis tilt during machining.

| More flexibility is provided when machining surfaces. The machining area can be extended past the drive surfaces to the edges of the main pattern. This allows the tool engagement to happen more gradually to protect the tool and maximize tool life.

The porting module has also been enhanced with the option to automatically add the link motion between the machining of the port inlet and outlet. The length and orientation of the link are calculated to ensure collision free motion. |

SWARF stripe milling SWARF stripe milling |

3-Axis

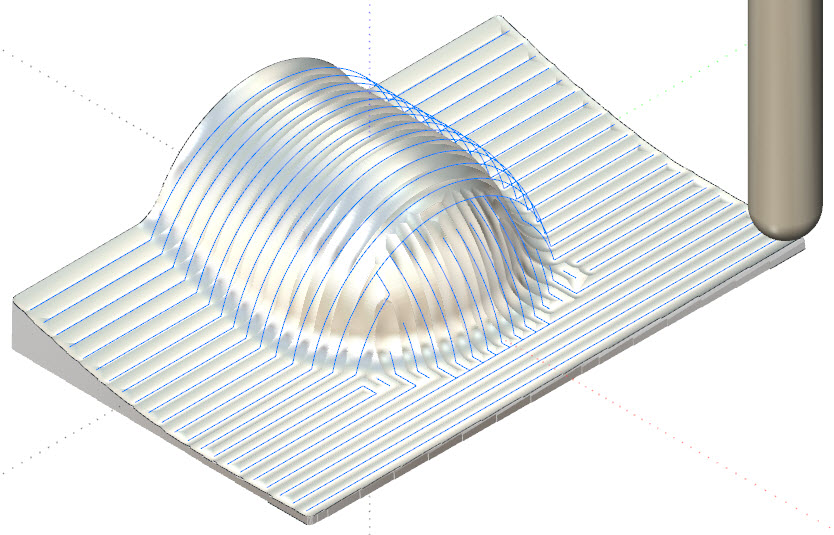

A new high speed machining module is launched with the 2015.04 release. Developed from the ground up to support the latest multithreaded 64 bit processing technology, the new finishing toolpaths offer huge performance improvements and motion optimized for high speed machining. Caching of intermediate data means editing and recalculation of toolpaths is lightning fast.

| A new optimize parallel cuts option solves the problem of larger cusps on vertical walls. Additional passes, perpendicular to the initial passes, are created in these areas and this can avoid the need for time consuming rest machining in these areas.Toolpath transform is now supported with the ability to rotate or translate to create a pattern with copies of the original toolpaths. This can reduce programming time and shorten the NC file on parts with many repetitive features. |  Hybrid parallel cuts Hybrid parallel cuts |

Simulation

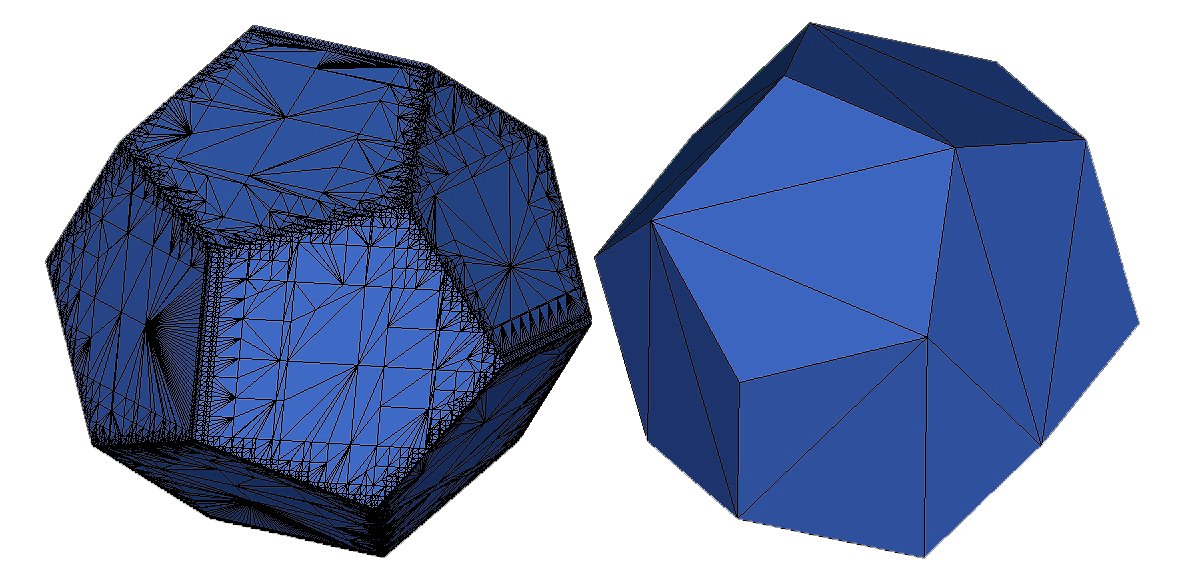

The STL mesh of the stock after material removal simulation has been much improved. Quality of the final mesh is enhanced and the number of triangles has been reduced making the mesh more suitable to use as a basis for subsequent rest machining.

| A new right mouse button context menu has been added to the simulation window. This allows the user to quickly access commonly required functions such as view and visibility options.

The machine definition has been improved with new features to make building complex machines easier. Multiple objects can be selected and manipulated together with new object highlighting showing exactly which parts of the machine are active. Transformations now have an angle property making it quicker and easier to define these. Collision detection has also been revised with new methods to define collision pairs, making it easier to define only the collision conditions you are looking for. |

Mesh decimation Mesh decimation |

The 2015.04 release is now available to all partners from the customer download area at www.ModuleWorks.com