Manufacturing Challenges

Skills Gap

Machine Complexity

Machine Availability

Machine Connectivity

Digital Enabled Business

Skills Gap

Machine Complexity

Machine Availability

Machine Connectivity

IoT/Industry 4.0 is the target vision of manufacturing companies. Getting there requires the intelligent and effective connection of heterogeneous hardware and software systems.

Digital Enabled Business

A well-designed online presence of hardware product portfolios has become vital to success. Companies require new and powerful ways to convincingly demonstrate their products online.

By digitalizing machines, processes and workflows you generate value that makes manufacturing more automated and sustainable at the same time. ModuleWorks is your partner for pursuing digitalization and delivering quality and precision.

Service Levels

ModuleWorks provides industry-proven software and efficient manufacturing solutions, from off-the-shelf software components to a full consultation on the best digitalization strategy for your products.

Off-the-Shelf Components

Enhance your manufacturing and get to market faster with our ready-made components. We offer cost-effective solutions for increased efficiency and quality.

Customized Solutions

Turn-Key Solutions

Solution Portfolio

Operator Education

ModuleWorks training tools give operators an ultra-realistic training experience on fully simulated machines to bridge the skills gap while optimizing machine availability and eliminating the risk of damage to production equipment.

Intuitive Programming

Our easy-to-use programming approach helps your operators to program parts on the CNC in an intuitive manner and enables you to maximize the productivity on the shop floor.

Machine Programming

Extend the shop floor programming capabilities of your CNC with our wide variety of milling and turning strategies combined with a flexible post-processing solution.

Process Analysis and Automation

ModuleWorks fully automated on-control programming and analysis tools empower operators to optimize multi-tasking machinery and increase shop floor productivity.

Program Verification

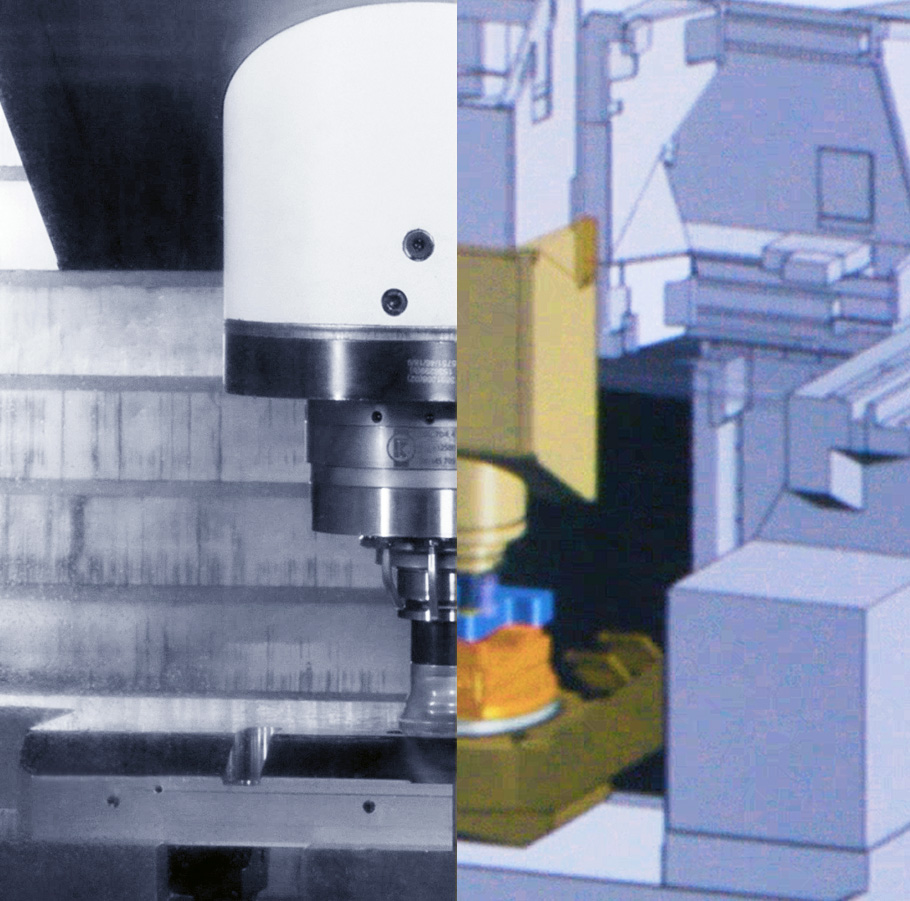

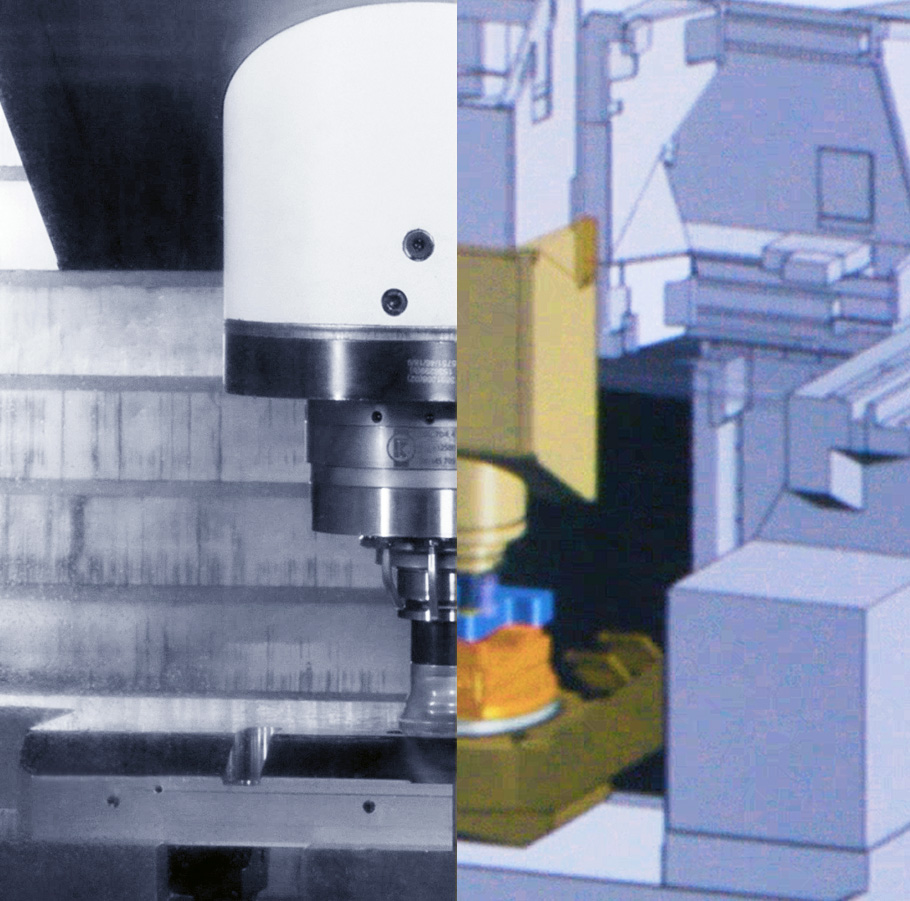

Our solutions also help to maintain stability and avoid interruptions in manufacturing processes by verifying programs before they are executed on the machine.

Machine Protection

From tool path verification to real-time collision avoidance, our intelligent, automated solutions support operators in all safety-critical processes to ensure production stability and continuous machine availability.

Digital Thread

To make 3D geometry data efficiently available without manual input, ModuleWorks offers Data Provisioning tools that streamline data up- and downstream.

Machine Demonstration

Machine Demonstration tools help you create persuasive marketing material on demand to efficiently demonstrate a machine’s unique benefits to potential partners.

Operator Education

ModuleWorks training tools give operators an ultra-realistic training experience on fully simulated machines to bridge the skills gap while optimizing machine availability and eliminating the risk of damage to production equipment.

Intuitive Programming

Our easy-to-use programming approach helps your operators to program parts on the CNC in an intuitive manner and enables you to maximize the productivity on the shop floor.

Machine Programming

Extend the shop floor programming capabilities of your CNC with our wide variety of milling and turning strategies combined with a flexible post-processing solution.

Process Analysis and Automation

ModuleWorks fully automated on-control programming and analysis tools empower operators to optimize multi-tasking machinery and increase shop floor productivity.

Program Verification

Our solutions also help to maintain stability and avoid interruptions in manufacturing processes by verifying programs before they are executed on the machine.

Machine Protection

From tool path verification to real-time collision avoidance, our intelligent, automated solutions support operators in all safety-critical processes to ensure production stability and continuous machine availability.

Digital Thread

To make 3D geometry data efficiently available without manual input, ModuleWorks offers Data Provisioning tools that streamline data up- and downstream.

Machine Demonstration

Machine Demonstration tools help you create persuasive marketing material on demand to efficiently demonstrate a machine’s unique benefits to potential partners.

Digital Factory in Numbers

Manufacturers trust in ModuleWorks

Shop Floor-Oriented Solutions

Your Partner for Success and Innovation

We believe in building long-term partnerships with our clients, working together to achieve shared goals and drive innovation.

Our ongoing partnership with ModuleWorks allows us to focus on our distinctive competencies to provide real user benefits more quickly, like releasing Protect My Machine/3D Twin to the market.

Johann Dietrich

Product Manager - Motion Control

Johann Dietrich

Product Manager - Motion Control

Over the course of the last years, the collaboration between FANUC Europe and ModuleWorks has developed into a true partnership creating mutual benefits towards the digitalization of manufacturing processes.

Dr. Wilfried Steiger

Team Leader Application Experts

Dr. Wilfried Steiger

Team Leader Application Experts

With ModuleWorks, we have chosen a partner, in a unique position as a single source provider, that makes tool path and simulation components accessible, affordable and usable.

Dr. Daniel Niederwestberg

Divisional Manager - Digital Twin

Dr. Daniel Niederwestberg

Divisional Manager - Digital Twin

To broaden our digital product portfolio and enhance operator interaction with the control, we have decided to work together with ModuleWorks.

Matteo Giugno

CNC Application Engineer

Team Leader

Matteo Giugno

CNC Application Engineer

Team Leader

The digital system enables our customers to make optimal use of their machining centers and keep their productivity at a constantly high level through preventive collision protection.

Domenik Kohli

Project Manager ProtectLine

Domenik Kohli

Project Manager ProtectLine

Our Experts in Digital Factory

Dr.-Ing. Sven Odendahl

Head of Technology

Digital Factory

Christoph Kückes

Global Sales & Business Development Manager