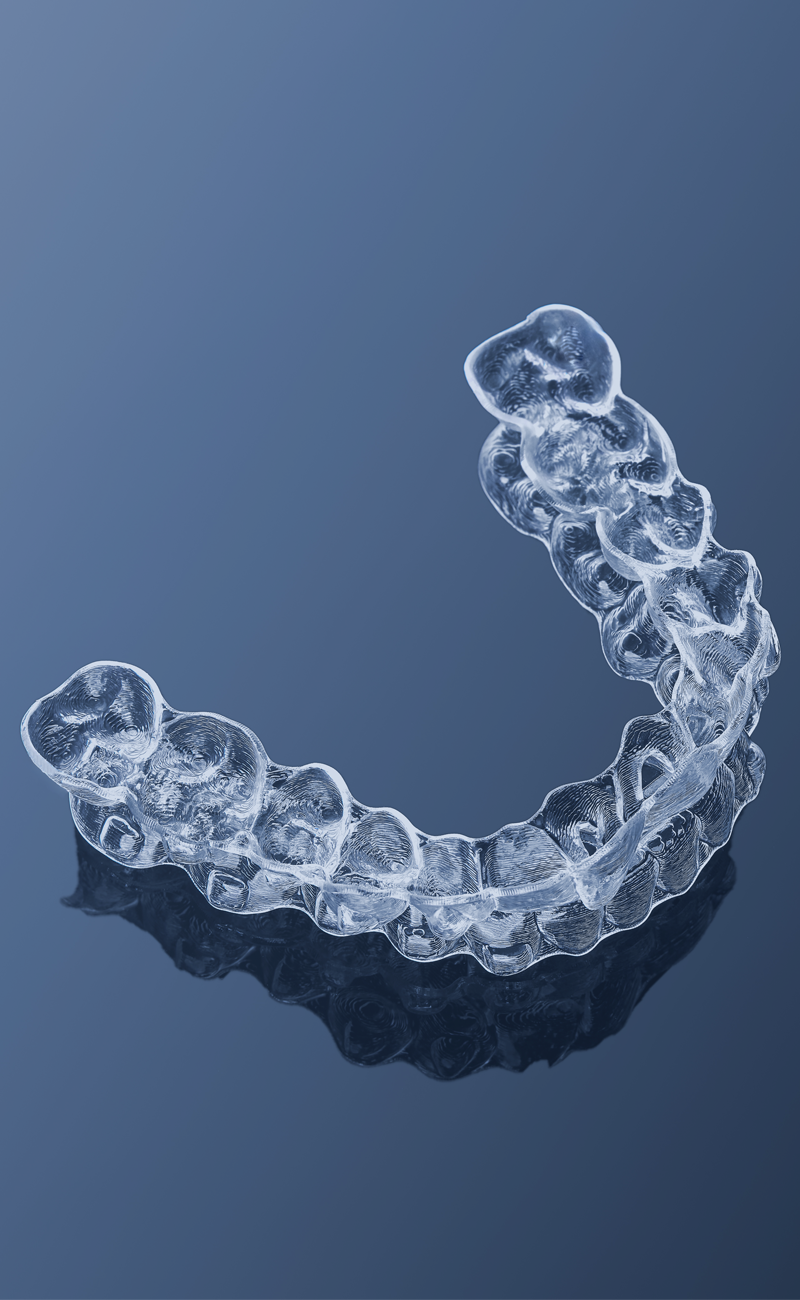

Digital dentistry refers to the application of digital technology in the field of dental care and dentistry. It encompasses a wide range of tools, techniques and workflows designed to improve accuracy, efficiency and patient outcomes.

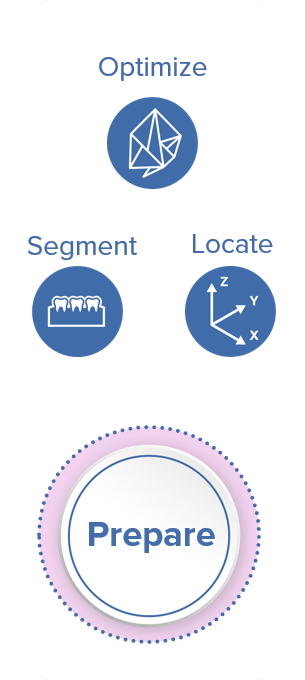

Bringing advanced functionality to the dental market and making it accessible is our aim. By integrating computer-aided tools from ModuleWorks, digital dentistry streamlines traditional dental procedures, enhances precision and reduces treatment times.

We digitalize and automate dentistry, empowering manufacturers, labs and practitioners to overcome challenges like rising costs, skill shortages and labour inefficiencies.

ModuleWorks Digital Dentistry Numbers

1700+

Person-Years

25K+

Installed Machines with ModuleWorks Dental CAM

90%

Market Share Industrial CAM Market

40%

Market Share Laboratory CAM Market

200+

Employees

200+

Developers

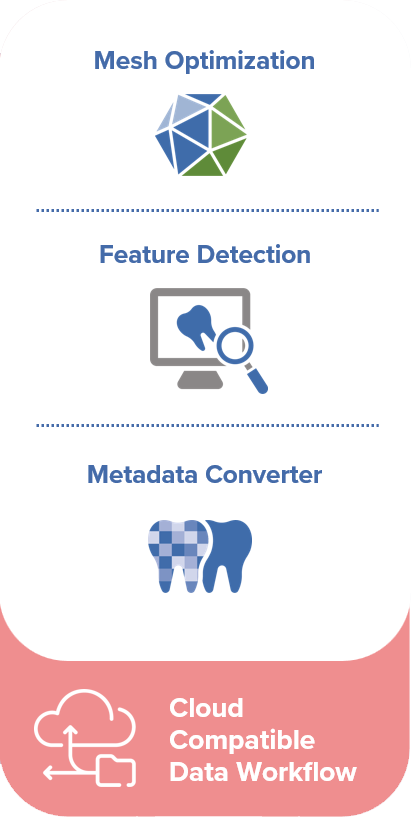

Technology Base for Digital Dentistry

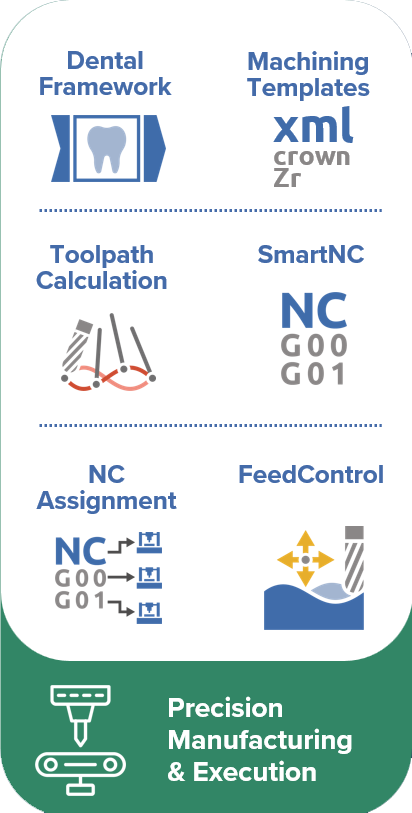

CNC Machining

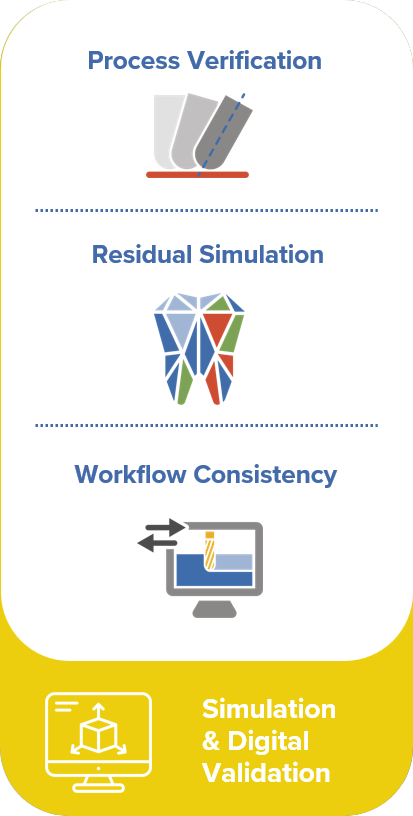

Simulation

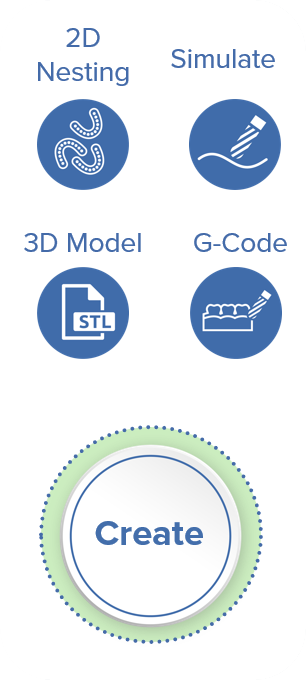

ModuleWorks Cutting and Machine Simulation offers high-performance toolpath and cutting simulation for milling & grinding of dental indications with the option of a full kinematic machine simulation. This component enables visualization of machining strategies and complex kinematic scenarios. Collision detection in 3-Axis, 4-Axis & 5-Axis allows correction of the toolpaths prior to NC code generation. This is particularly useful in R&D when developing validated machining strategies.

3D Printing

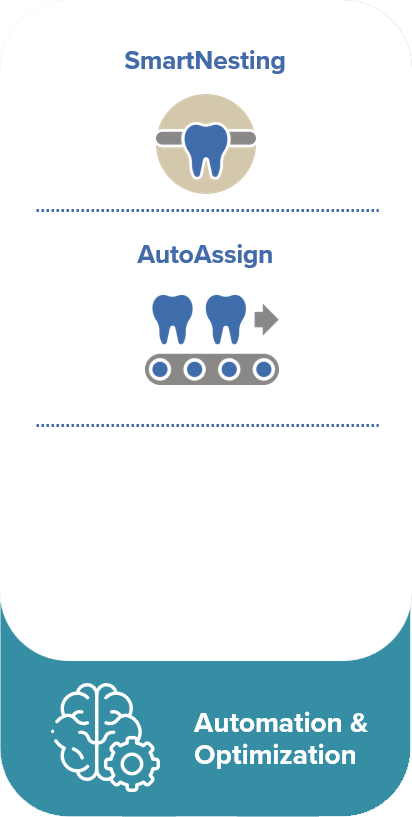

Additive for Dental

Additive for Dental delivers a dedicated feature-set to enhance productivity in additive manufacturing of dental indications, including support for SLM, SLA, DLP and Hybrid-AM processes, all from one integrated high-performance kernel. This enables a fast time-to-market for comprehensive solutions that go beyond the standard functionality.

Robotics

Robotics Core for Dental

ModuleWorks Robotics Core for Dental enables robotics fabrication in Digital Dentistry by connecting a comprehensive range of Dental CAM machining toolpaths to advanced robotics hardware. In the offline programming environment, robotic machining is achieved using ModuleWorks industrial high-performance kinematics solver and NC code Post Processor Framework which are adaptable to diverse robotics hardware setups.

Your Partner for Success and Innovation

Our Experts in Digital Dentistry

Everyone in the world needs good dental healthcare. Through strong partnerships, we deliver high-quality prosthetics with maximum efficiency and precision to ensure the best possible outcomes for every patient.

Ben Weber

Head of Business

Digital Dentistry

Soroosh Eghbali

Head of Technology

Digital Dentistry

From design to production, we transform digital dentistry with smart manufacturing solutions. Whether it’s CNC, 3D printing, or robotics, our software enables seamless automation, helping industry leaders scale and innovate.