ModuleWorks announces the successful testing of its digital manufacturing software components on a Snapdragon ARM (Advanced RISC Machines) processor running Windows. The results confirm the stability and performance of the software on the ARM architecture, opening the prospect of running high-end CAM solutions on energy efficient platforms.

As CAM vendors keep an eye on advances in computer hardware, the performance of ARM processors is attracting attention. These processors have the potential to offer fast toolpath calculations and advanced 3D simulations with a low energy footprint. This opens the door to a wide range of high-performance CAM solutions for mobile, lightweight and cloud-connected devices.

The hurdle for CAM vendors is adapting their software to run natively on the ARM architecture. This includes not only the software they develop in house, but also the software they purchase and integrate from partner companies like ModuleWorks. For this reason, ModuleWorks decided to put its CAM software engine to the test.

Miguel Johann, Product Director at ModuleWorks explained:

“Our digital manufacturing software components integrated in many of the leading CAD-CAM and CNC solutions. When migrating to ARM systems, our partners need a guarantee that ModuleWorks runs seamlessly as native software in ARM environments. We are very proud to announce that it does.”

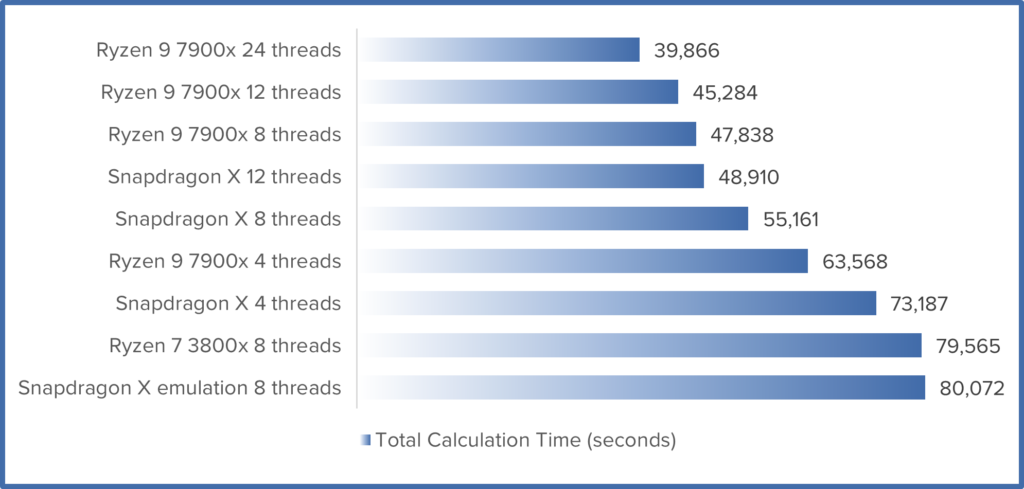

ModuleWorks tested its CAM Engine on the latest ARM (Snapdragon X Elite) and x86 (AMD Ryzen 7 and 9) processors. The ModuleWorks Engine ran reliably and consistently on both, generating identical toolpath results.

In terms of performance, the times for a benchmark toolpath calculation are shown here:

and a Windows 11 desktop with AMD Ryzen 9 and 7 processors.1

The results show that CAM vendors can expect the ModuleWorks native ARM software to deliver a processing performance similar to the x86 version, especially on 12 threads. Although not as fast as the x86 version, the performance is high for a laptop.

It is also possible to run the ModuleWorks x86 software in emulation mode on the Snapdragon SoC. However, running ModuleWorks in native ARM is more than 30% faster, so it makes sense to take advantage of native ARM on the Snapdragon.

What makes the Snapdragon SoC particularly attractive for CAM is its ability to deliver a high performance while maintaining lower energy consumption. This not only extends battery life but also reduces heat output, allowing devices to stay cooler under heavy computational workloads. For CAM vendors this creates the opportunity to develop high-end solutions for lightweight, portable devices, making it easier to work on-site or in remote locations.

“CAM on ARM is an exciting development for the industry”, said Miguel Johann. “Making our CAM Engine ARM-ready means our partners can press ahead with the development of CAM solutions that are energy efficient.”

The ModuleWorks CAM Engine is available as native ARM software libraries in addition to the x86 libraries for Windows and MAC OS systems.

1 The tests were conducted at the ModuleWorks development facility in Aachen, Germany. The results are based on the current generation of Snapdragon X (Snapdragon® X Elite X1E-78-100, 12-core) on the host laptop. With expected upgrades in this technology in future as well as upgrades to Windows, performance may improve and ModuleWorks expects to repeat the tests in the future.

About Qualcomm’s Snapdragon X

Qualcomm’s Snapdragon X is a cutting-edge ARM-based processor designed to deliver exceptional performance and energy efficiency. It is particularly well-suited for portable devices, offering powerful computing capabilities while maintaining low power consumption. Snapdragon X is a key component in some of the latest generation of Windows on ARM devices, ensuring smooth and efficient operation of demanding applications.

About ModuleWorks

ModuleWorks is at the forefront of digital manufacturing software, playing a key role in enabling the efficient production of increasingly complex parts in an environmentally sustainable way. As a strategic partner to leading CAD/CAM vendors, CNC control makers, machine tool builders and cutting tool manufacturers, ModuleWorks develops software that powers solutions throughout the manufacturing industry which contributes to 16% of global GDP worth $16 trillion per year.

Founded in 2003, ModuleWorks has grown to over 200 employees and already invested 1,700 person-years of software development in toolpath and simulation technologies that form the core of manufacturing processes. In the CAD/CAM area alone, ModuleWorks has a market share of 90%, enhancing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software worldwide. With a comprehensive portfolio of cutting-edge software components and the capacity to address emerging and niche technologies like AI, cloud, automation, additive, robotics and digital dentistry, ModuleWorks is committed to shaping the future of digital manufacturing with its partners, empowering the industry to Get There Faster.