The dental service industry is a massive $500 billion global market (source: Precedence Research). We estimate that $15 billion is spent on manufacturing alone – on machines, tools and labour.

The best dental care relies on high quality manufacturing of the indications. Like all manufacturing, the quality of the final product depends on the precision, efficiency and reliability of the technology used. With the industry facing challenges from shortage of labour, increased competition and higher costs of innovation, the future lies in automated, AI-driven solutions.

At this year’s IDS (25 – 29 March) in Cologne, ModuleWorks is showcasing a new range of smart solutions that address these challenges. By harnessing the power of AI and cloud technology, ModuleWorks Dental CAM modules streamline data preparation, reduce manual steps and minimize iterations, enhancing the efficiency and quality of manufacturing in restorative dentistry, orthodontics and implantology.

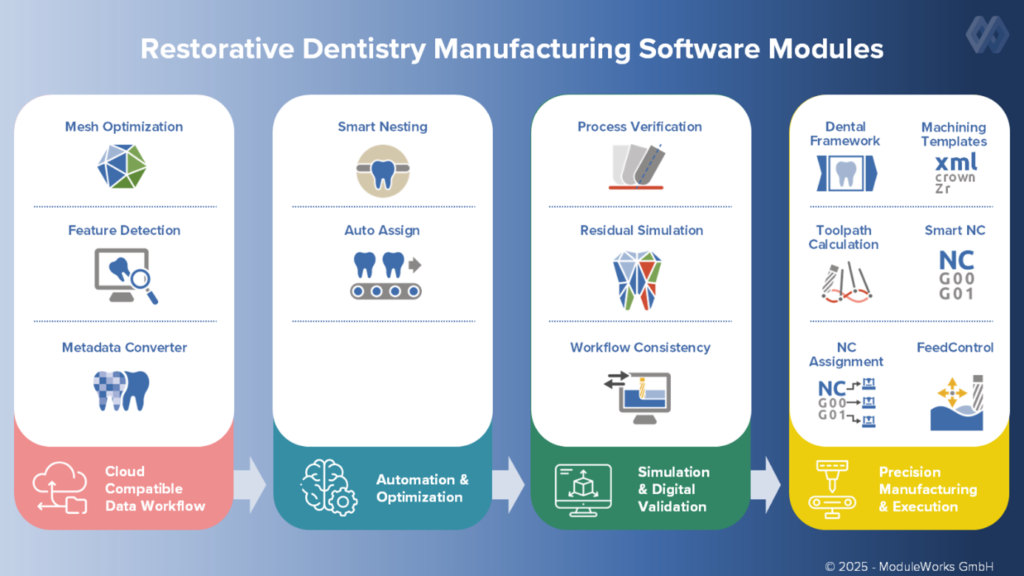

Scalable Automation for Restorative Dentistry

These powerful software modules are designed for seamless integration in desktop applications and cloud-based solutions. For dental labs and clinics, this translates into fast, cost-effective implementation of scalable, accessible and highly automated dental manufacturing processes.

With these modules, dental professionals overcome traditional software limitations and create a connected, more profitable production environment.

Cloud Compatible Data Workflow: Cloud-ready pipeline for ingesting, optimizing and preparing the design and manufacturing data. Automatic mesh healing, feature recognition and metadata exchange ensure clean, structured inputs for a smooth, integrated workflow.

Automation & Optimization: Smart Nesting and AutoAssign reduce manual interactions in the nesting workflow by automating key processes. Integrated into the cloud workflow, these modules optimize efficiency, accuracy and task distribution.

Simulation & Digital Validation: Simulation & Digital Validation ensure process verification, error checking and digital validation for a fully automated machining workflow. Simulated models can be calculated in the cloud and made available throughout the design-milling workflow.

Precision Machining & Execution: These modules power the final toolpath generation and machine-specific optimization, with the possibility of cloud-based storage for machining templates and post-processors to ensure a seamless, scalable workflow.

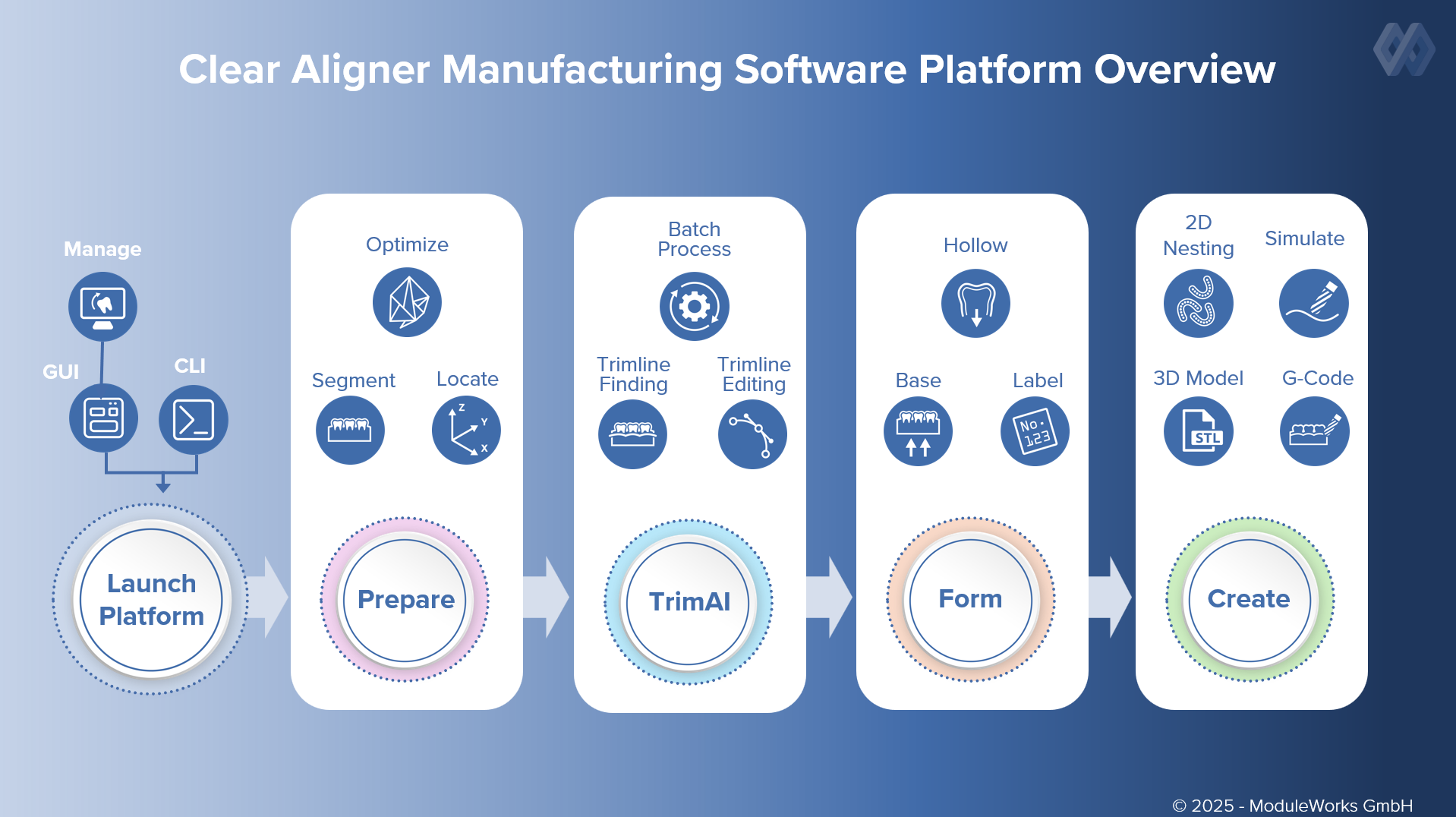

Orthodontics – Automated Efficiency for Clear Aligner Manufacturing

ModuleWorks recently launched its innovative clear aligner software, streamlining clear aligner production with AI-driven automation.

This all-in-one production framework is designed for clear aligner manufacturers, software vendors and hardware vendors. Powered by the latest AI technology, it optimizes the clear aligner manufacturing process by:

- Enhancing Quality: Consistent, high-precision aligners.

- Increasing Efficiency: Streamlined workflows that boost productivity.

- Driving Profitability: Reduced costs and maximized returns.

- Improving Patient Experience: Delivering better outcomes faster.

To learn more about next-generation clear aligner manufacturing, take a look at this video:

Precision in Implantology

The success of every implantology treatment depends on complex manufacturing processes. Even the slightest deviation in an implant’s structure can lead to complications, affecting osseointegration and patient well-being.

Large scale manufacturers need flexible, highly efficient solutions with high performance calculations, the ability to be deployed over multiple sites and optimized metal machining for complex machines.

Solutions powered by ModuleWorks achieve:

- Enhanced Surface Quality

- Reduced Machining Time

- Reduced Tool Wear

ModuleWorks software offers a full range of high-performance turning and multi-axis milling toolpaths, including constant engagement milling. Advanced features like FeedControl ensure optimal feed rates for efficient, automated manufacturing. Integrators can pick and choose the modules they need for building flexible, tailored solutions.

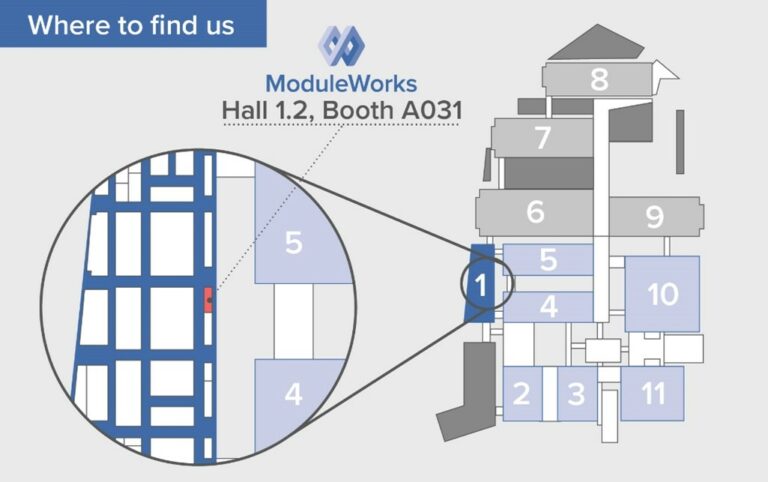

ModuleWorks at IDS 2025

All these solutions and more will be on show at the ModuleWorks booth at IDS 2025 – Hall 1.2, Booth A031. Our digital dentistry experts will be there and are looking forward to connecting with you.

Book a meeting with our global team:

Explore how our technologies can help you meet the challenges in digital dentistry. Book a meeting with an expert here: Book a meeting

We look forward to seeing you in Cologne!