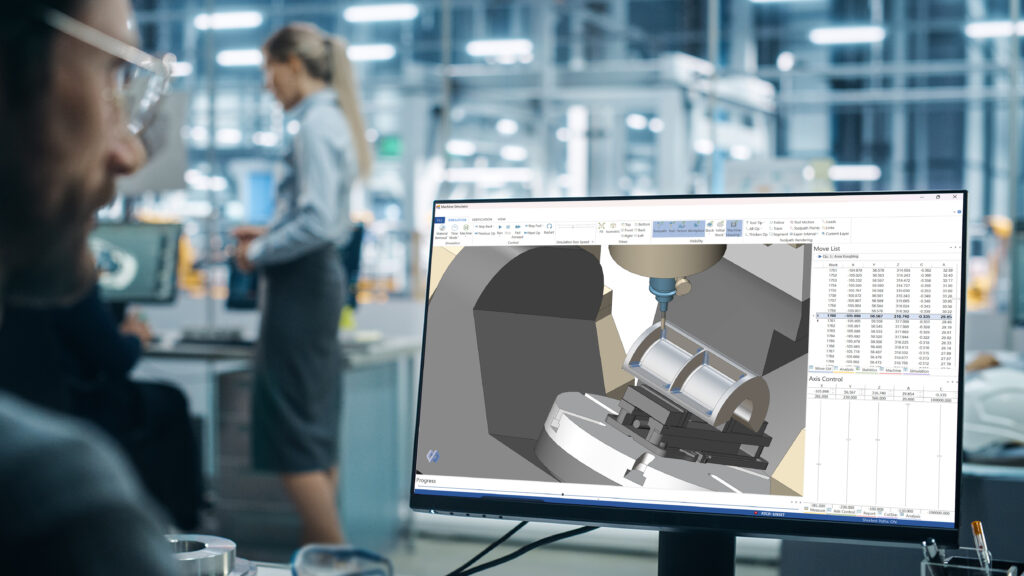

ModuleWorks and Toolpath Announce Technology Partnership Driving Cloud-Based CAM Automation

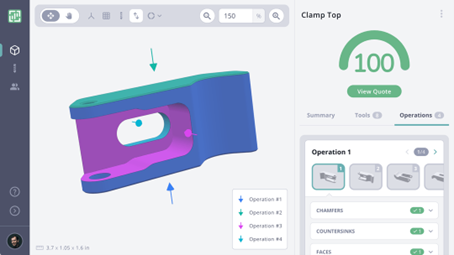

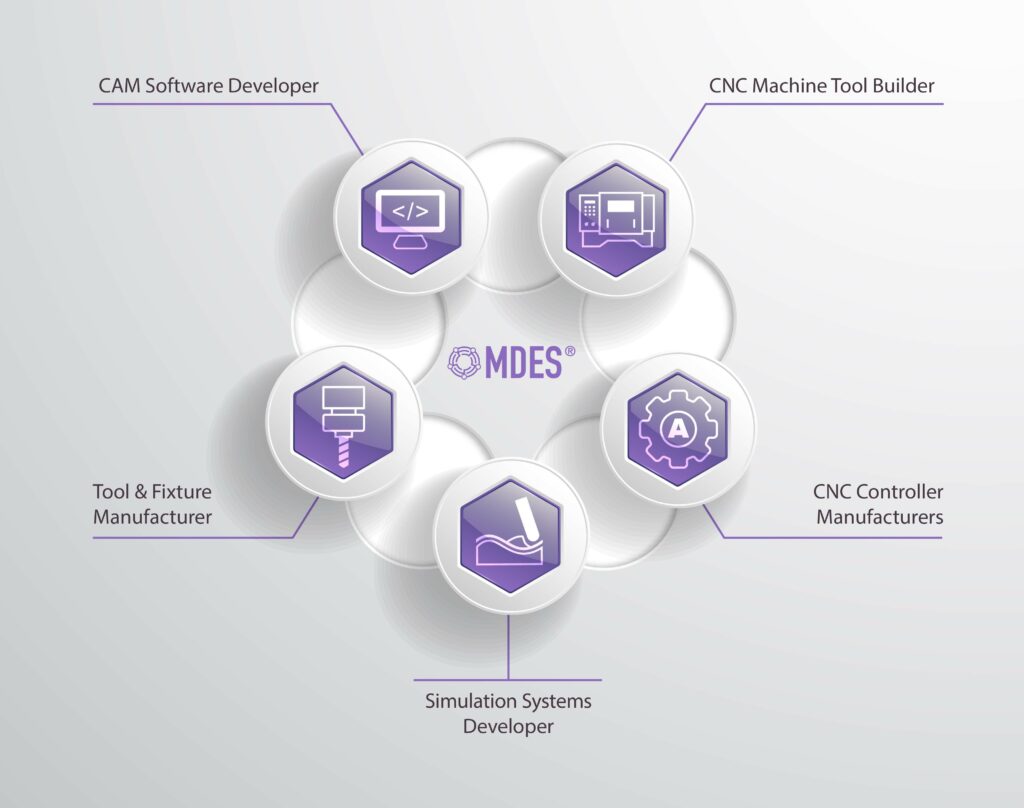

ModuleWorks, a leading innovator in toolpath generation and simulation software for digital manufacturing, and Toolpath, a developer of a new cloud-based, AI-driven manufacturing workflow automation platform, have signed a multi-year technology partnership focusing on accelerated deployment of innovative cloud computing technology for machining estimation and CAM automation. The ModuleWorks and Toolpath teams outside the ModuleWorks […]