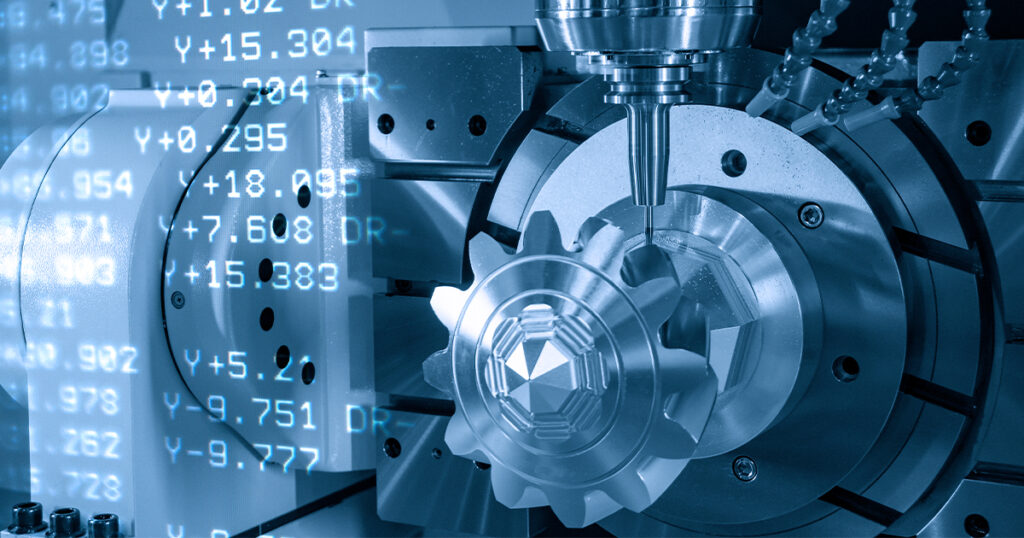

Post-Processors are crucial for ensuring that the CAM-generated toolpaths are accurately and efficiently executed by the CNC machine tools and robots and tailored to their specific requirements.

ModuleWorks offers an advanced solution called Post-Processor Framework (PPF) that uses a custom postscript to generate NC-Code from the output of the ModuleWorks kinematic solver (MultiXPost) or from any other source. The component is useful for companies that are developing software solutions that need to output an NC code to run a robot or machine. This includes CAD/CAM software developers, machine tool builders, robot OEMs, or integrators planning to develop or use Post-Processors.

Major Challenges

Supporting Modern Machine Tools and Robots

As the technology evolves, more advanced and modern machine tools and robots are being developed. CAM software needs a flexible solution that can support all the NC dialects supported by these machine tools and robots.

Ensuring Accuracy of the Operation

Due to the complexity of the toolpaths (especially in the case of 5-axis machines or robots) and even for multi-axis additive manufacturing processes, the individual toolpath points must be accurately translated to ensure precision.

Simplifying Post-Processor Development

Historically, developing Post-Processors for machine tools or robots has been viewed as a specialized field requiring expert knowledge. However, with the growing reliance on CNC machines among manufacturers, there is now a greater need for simplified applications for Post-Processor development than ever before.

Collision Avoidance

Many CAM software simulations and even collision avoidance systems rely on output NC code generated from the toolpath to accurately predict machine tool movements and to avoid any potential collisions. Moreover, Post-Processors also need internal checks to maintain the accuracy of the output data thereby avoiding any collisions due to an incorrect NC code.

Solution Offered by ModuleWorks

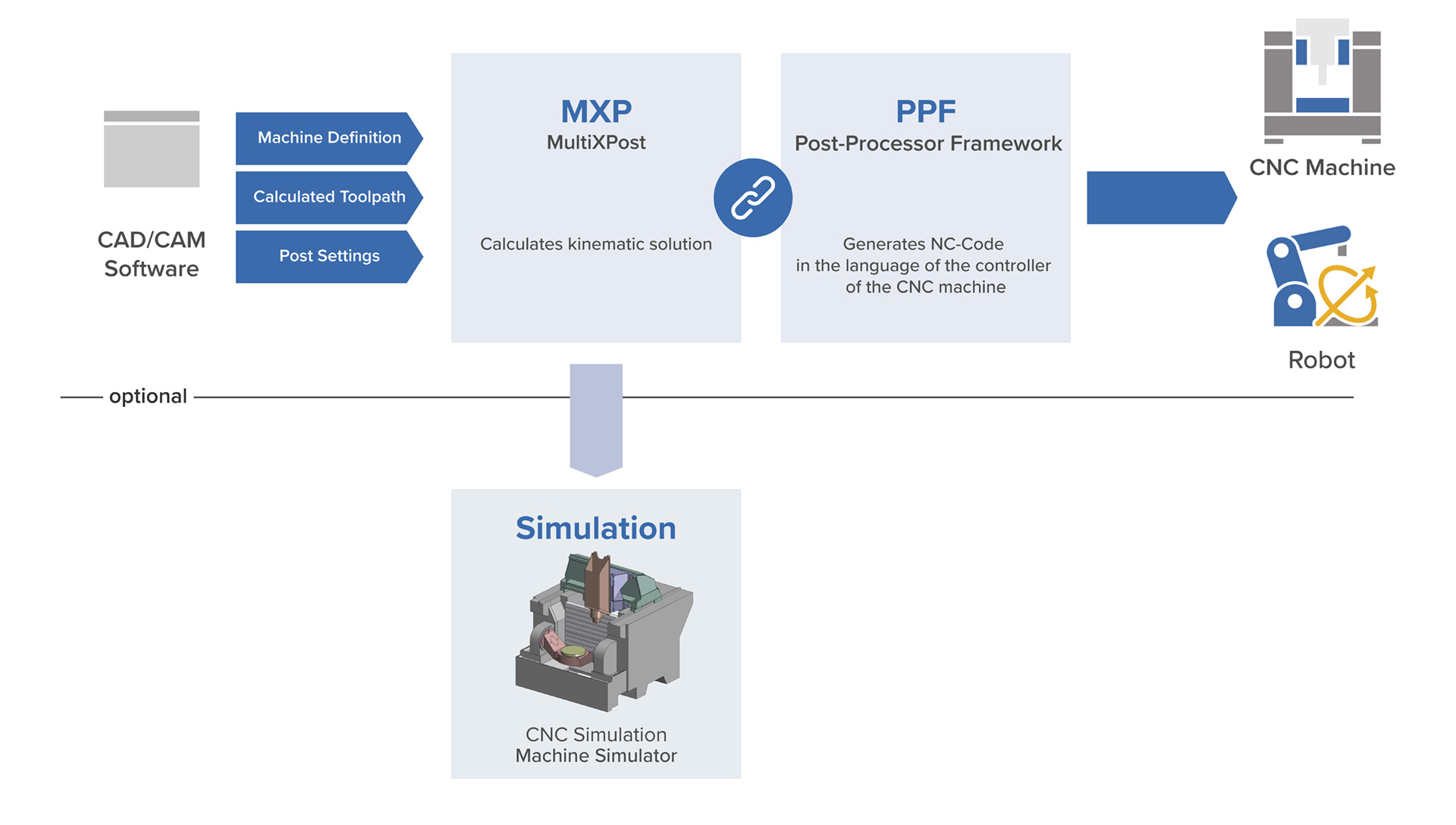

ModuleWorks Post-Processor Framework (PPF) lets you script the NC-output for any custom machine tool or robot and stream it directly to that device. PPF uses ModuleWorks MultiXPost as a front-end component to resolve any machine or robot kinematic. Alternatively, any other API can be used to integrate the software into a toolpath environment, independent of the ModuleWorks toolpath calculation.

PPF runs on a network server and on any operating system with python support.

Workflow for NC Code Generation using ModuleWorks Post-Processor Framework (PPF)

Key Highlights

Modern Architecture

- Many Post-Processor environments rely on outdated architecture and legacy programming languages, which are difficult to learn and limited in functionality.

- PPF is a modern solution based on Python, a popular, easy-to-learn language that is widely used and familiar to application engineers.

- PPF offers greater flexibility and functionality, with the ability to integrate various components and APIs, surpassing the capabilities of legacy systems.

- With PPF, users can utilize an external posting server to generate NC code seamlessly while continuing to use the CAM software without any interruptions.

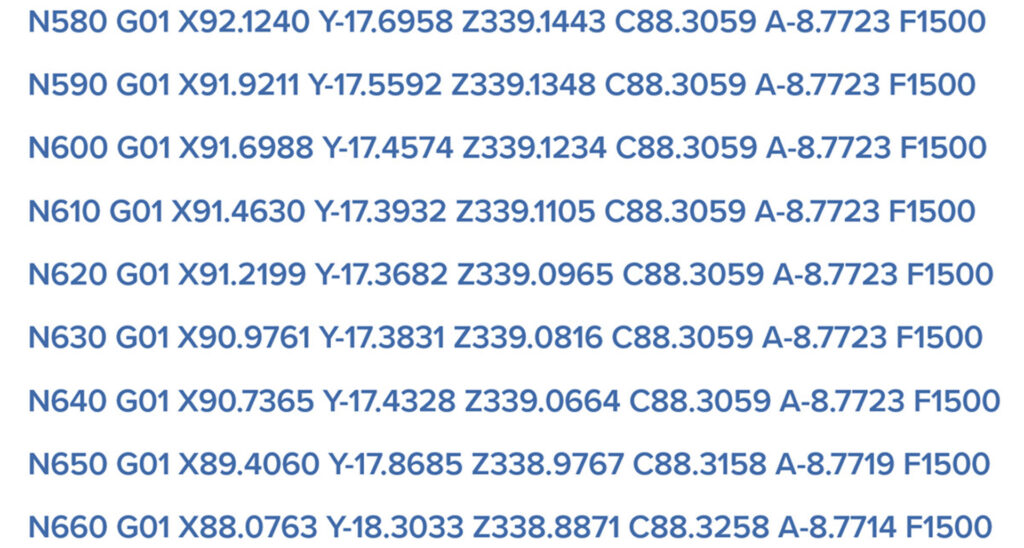

Rapid Calculation of NC-Code

- PPF can easily and reliably manage very large toolpaths, with several million lines of NC code for multi-axis machining.

- With special capabilities for ultra-precision machining, PPF delivers nanometer-accurate NC code output and supports millions of lines of NC code for high-end optical parts.

- PPF engine’s streaming mode supports billions of lines of NC code for PBF additive manufacturing, enabling the production of full stacks of parts with micro-level details.

- PPF is the leading technical framework, supporting everything from basic milling and turning to the most complex kinematics and processes in additive manufacturing, ultra-precision machining, and robotics. It is a single framework that meets all the needs of CAM systems.

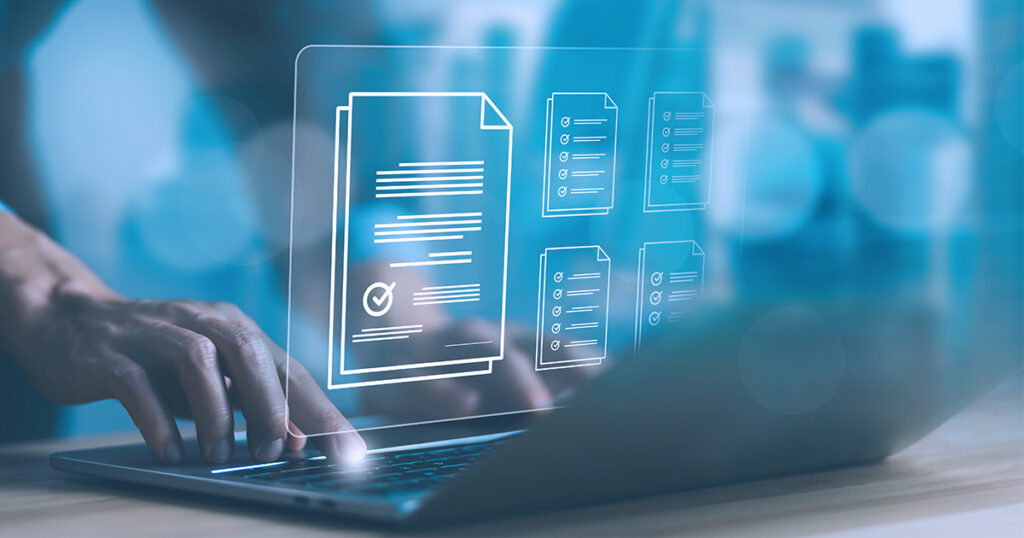

Complete PPF Documentation

- PPF User documentation: Complete documentation to show the customers how to get started and how to create and modify posts with sections like:

- Installation

- Introduction & Getting Started

- Sample Posts

- Tutorials & Concepts

- API Documentation

- PPF Developer documentation: Description for developers who want to integrate PPF in their own CAD/CAM system with sections like:

- PPF architecture & versioning

- C++ Integration

- .NET integration

Key Benefits

Industry-proven solution for NC code generation

Reduce development and maintenance expenses by integrating fully-featured Post-Processor component

Flexible and customized scripting for any controller (ISO-based, Sinumerik, Fanuc, Heidenhain,...) or output format

Fast NC code generation, for processing millions of lines of code quickly

Open kinematics format definition through MultiXPost Robotics Machine

API for easy integration into existing CAM solutions through C# or C++